How to test a relay for high-power applications?

Relays are essential components in high-power applications, ranging from industrial machinery to automotive systems. These devices are responsible for controlling the flow of electricity and are critical to ensuring the proper functioning of various electrical systems. To maintain optimal performance, it is crucial to regularly test relays to detect any faults or malfunctions before they cause serious damage.

Testing a relay for high-power applications requires a systematic approach to ensure accurate results and reliable performance. In this article, we will discuss the steps involved in testing a relay effectively.

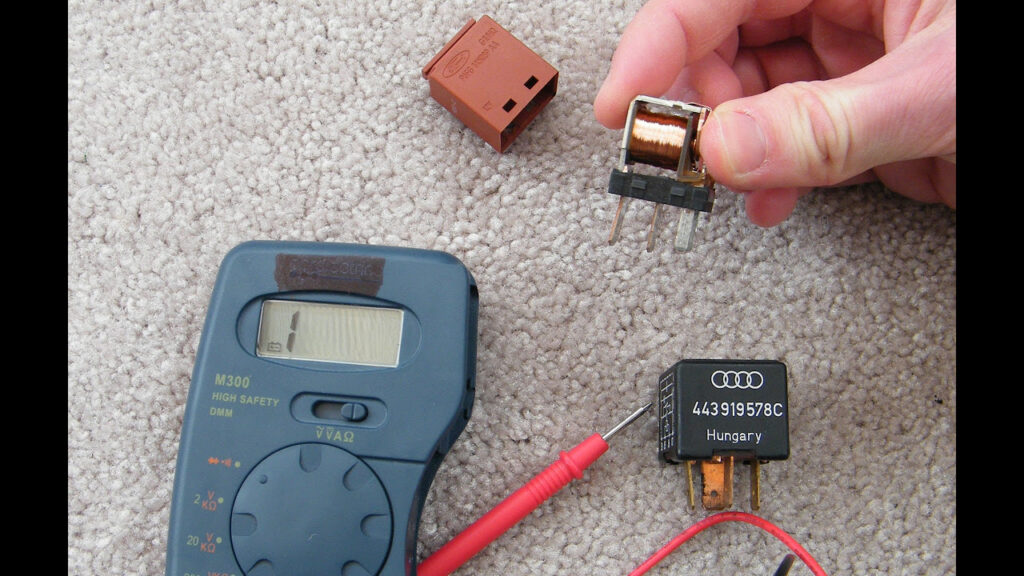

Step 1: Visual Inspection

The first step in testing a relay is to conduct a visual inspection of the device. Check for any signs of physical damage, such as burns, cracks, or corrosion. Inspect the relay contacts for signs of wear or arcing. Any visible damage can indicate a potential fault in the relay and may require further testing.

Step 2: Continuity Test

After the visual inspection, perform a continuity test to check the integrity of the relay contacts. Use a multimeter to measure the resistance across the relay contacts. A reading close to zero indicates that the contacts are in good condition, while a high resistance reading may indicate a faulty relay.

Step 3: Coil Resistance Test

Next, test the coil resistance of the relay to ensure that it is within the specified range. Use a multimeter to measure the resistance across the relay coil terminals. Compare the reading to the manufacturer’s specifications to determine if the relay is functioning correctly.

Step 4: Voltage Test

Conduct a voltage test to verify that the relay can handle the specified voltage for high-power applications. Apply the recommended voltage to the relay coil and check that the contacts switch properly. Any issues with the operation of the relay under load can indicate a potential problem.

Step 5: Load Test

Finally, perform a load test to evaluate the relay’s performance under high-power conditions. Connect the relay to a load device and monitor its operation while applying the rated current. Ensure that the relay can handle the load without overheating or malfunctioning.

By following these steps, you can effectively test a relay for high-power applications and ensure its reliable performance in critical electrical systems. Regular maintenance and testing of relays are essential to prevent downtime and costly repairs. Remember to consult the manufacturer’s guidelines and specifications when testing relays to ensure accurate results.

Stay tuned for more tips and guides on testing electrical components for high-power applications.

How to test a relay for high-power applications?

Relays are essential components in high-power applications, ranging from industrial machinery to automotive systems. These devices are responsible for controlling the flow of electricity and are critical to ensuring the proper functioning of various electrical systems. To maintain optimal performance, it is crucial to regularly test relays to detect any faults or malfunctions before they cause serious damage.

Testing a relay for high-power applications requires a systematic approach to ensure accurate results and reliable performance. In this article, we will discuss the steps involved in testing a relay effectively.

Step 1: Visual Inspection

The first step in testing a relay is to conduct a visual inspection of the device. Check for any signs of physical damage, such as burns, cracks, or corrosion. Inspect the relay contacts for signs of wear or arcing. Any visible damage can indicate a potential fault in the relay and may require further testing.

Step 2: Continuity Test

After the visual inspection, perform a continuity test to check the integrity of the relay contacts. Use a multimeter to measure the resistance across the relay contacts. A reading close to zero indicates that the contacts are in good condition, while a high resistance reading may indicate a faulty relay.

Step 3: Coil Resistance Test

Next, test the coil resistance of the relay to ensure that it is within the specified range. Use a multimeter to measure the resistance across the relay coil terminals. Compare the reading to the manufacturer’s specifications to determine if the relay is functioning correctly.

Step 4: Voltage Test

Conduct a voltage test to verify that the relay can handle the specified voltage for high-power applications. Apply the recommended voltage to the relay coil and check that the contacts switch properly. Any issues with the operation of the relay under load can indicate a potential problem.

Step 5: Load Test

Finally, perform a load test to evaluate the relay’s performance under high-power conditions. Connect the relay to a load device and monitor its operation while applying the rated current. Ensure that the relay can handle the load without overheating or malfunctioning.

By following these steps, you can effectively test a relay for high-power applications and ensure its reliable performance in critical electrical systems. Regular maintenance and testing of relays are essential to prevent downtime and costly repairs. Remember to consult the manufacturer’s guidelines and specifications when testing relays to ensure accurate results.

Stay tuned for more tips and guides on testing electrical components for high-power applications.