How to Read Data from a Pressure Sensor

Pressure sensors are crucial devices used in a wide range of applications, from automotive and manufacturing to medical and environmental monitoring. These sensors measure the force exerted on them by a liquid or gas, converting it into an electrical signal that can be interpreted and analyzed. In this article, we will discuss how to read data from a pressure sensor and make sense of the information it provides.

Understanding the Basics of Pressure Sensors

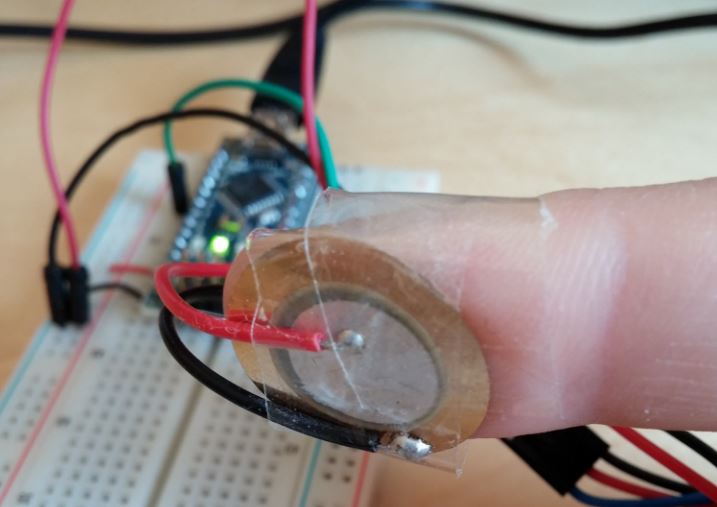

Before we dive into the nitty-gritty of reading data from pressure sensors, it’s essential to understand how these sensors work. Pressure sensors consist of a sensing element that deforms in response to the force applied by the fluid or gas. This deformation generates a change in electrical resistance, capacitance, or voltage, which is then converted into a signal that can be read and interpreted by a connected device.

There are various types of pressure sensors available, including piezoresistive, capacitive, and piezoelectric sensors, each designed for specific applications and environments. Understanding the type of pressure sensor you are working with is crucial before attempting to read data from it.

Steps to Read Data from a Pressure Sensor

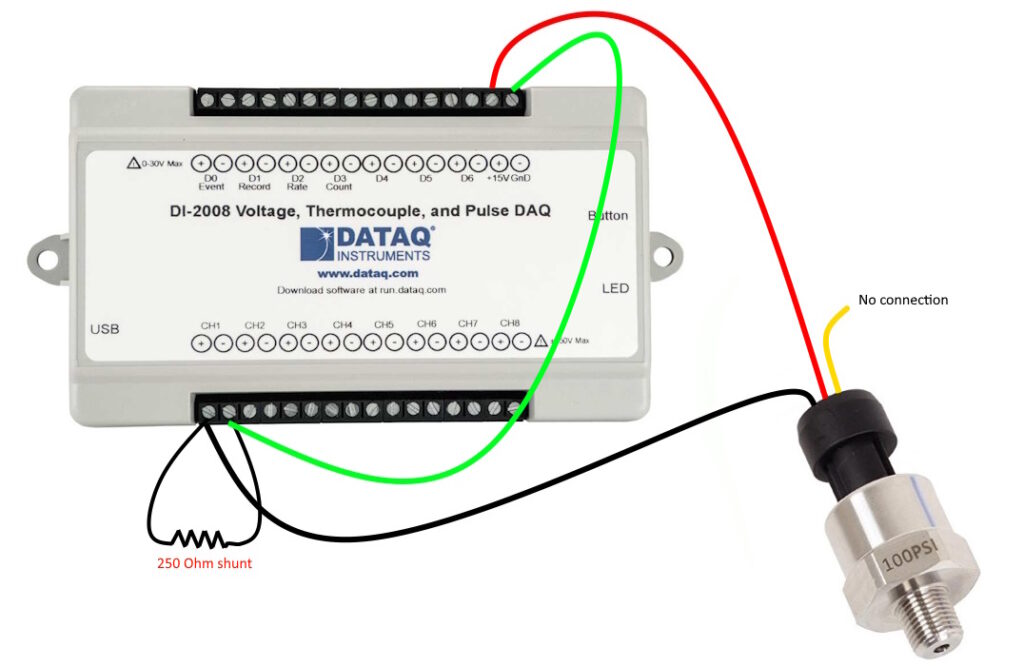

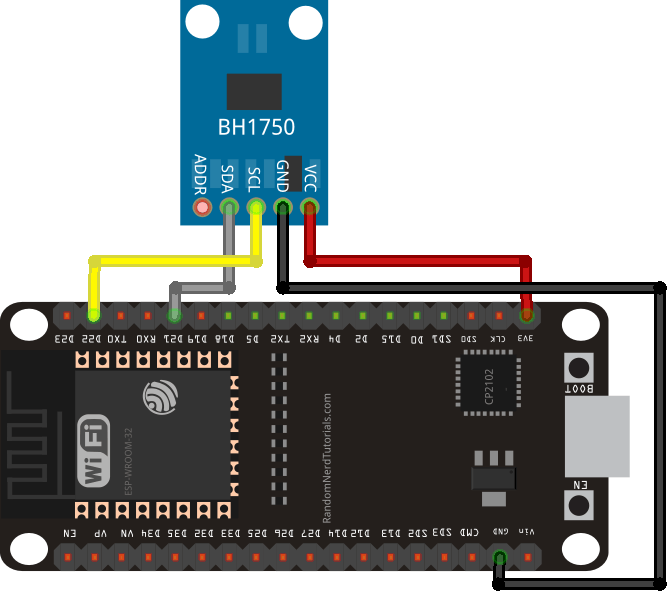

1. Connect the Sensor: The first step in reading data from a pressure sensor is to ensure that the sensor is properly connected to a compatible device, such as a microcontroller or data acquisition system. Check the datasheet of the sensor for the correct pinout and connection details.

- Calibration: Pressure sensors need to be calibrated before use to ensure accurate readings. Follow the calibration procedure outlined in the sensor’s datasheet or user manual.

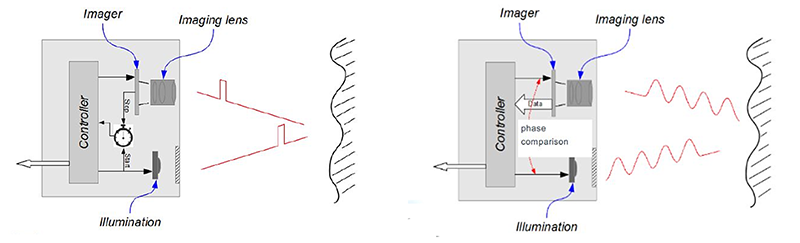

- Read the Data: Once the sensor is connected and calibrated, you can start reading data from it. Depending on the type of sensor, you may need to use analog-to-digital conversion techniques to interpret the signal.

- Interpret the Data: The data read from the pressure sensor will typically be in the form of voltage, current, or resistance values. You will need to convert these values into pressure units using the sensor’s calibration curve or equation.

- Data Analysis: Analyze the pressure data collected from the sensor to gain insights into the system’s performance or operating conditions. This may involve plotting graphs, calculating trends, or setting up alerts based on predefined thresholds.

Tips for Reading Data from a Pressure Sensor

Reading data from a pressure sensor can be a complex and challenging task, but with the right approach, it can provide valuable information for various applications. Here are some tips to consider when working with pressure sensors:

- Check the Sensor’s Data Sheet: The sensor’s datasheet contains crucial information about its specifications, pinout, calibration, and connection details. Always refer to the datasheet when setting up or reading data from the sensor.

- Use Proper Signal Conditioning: Depending on the sensor type and output signal, you may need to apply signal conditioning techniques such as amplification, filtering, or linearization to ensure accurate data readings.

- Consider Environmental Factors: Pressure sensors are sensitive to environmental factors such as temperature, humidity, and vibration. Make sure to account for these factors when reading data from the sensor to avoid inaccuracies.

By following these tips and steps, you can effectively read data from a pressure sensor and leverage the information it provides for your specific application or project. Remember to consult the sensor’s datasheet and user manual for accurate setup and calibration instructions to ensure reliable and precise data readings.

Pressure sensors play a crucial role in modern technology, and being able to read data from them accurately is essential for many applications. With the right knowledge and approach, you can harness the power of pressure sensors to monitor and analyze pressure levels effectively.

How to Read Data from a Pressure Sensor

Pressure sensors are crucial devices used in a wide range of applications, from automotive and manufacturing to medical and environmental monitoring. These sensors measure the force exerted on them by a liquid or gas, converting it into an electrical signal that can be interpreted and analyzed. In this article, we will discuss how to read data from a pressure sensor and make sense of the information it provides.

Understanding the Basics of Pressure Sensors

Before we dive into the nitty-gritty of reading data from pressure sensors, it’s essential to understand how these sensors work. Pressure sensors consist of a sensing element that deforms in response to the force applied by the fluid or gas. This deformation generates a change in electrical resistance, capacitance, or voltage, which is then converted into a signal that can be read and interpreted by a connected device.

There are various types of pressure sensors available, including piezoresistive, capacitive, and piezoelectric sensors, each designed for specific applications and environments. Understanding the type of pressure sensor you are working with is crucial before attempting to read data from it.

Steps to Read Data from a Pressure Sensor

1. Connect the Sensor: The first step in reading data from a pressure sensor is to ensure that the sensor is properly connected to a compatible device, such as a microcontroller or data acquisition system. Check the datasheet of the sensor for the correct pinout and connection details.

- Calibration: Pressure sensors need to be calibrated before use to ensure accurate readings. Follow the calibration procedure outlined in the sensor’s datasheet or user manual.

- Read the Data: Once the sensor is connected and calibrated, you can start reading data from it. Depending on the type of sensor, you may need to use analog-to-digital conversion techniques to interpret the signal.

- Interpret the Data: The data read from the pressure sensor will typically be in the form of voltage, current, or resistance values. You will need to convert these values into pressure units using the sensor’s calibration curve or equation.

- Data Analysis: Analyze the pressure data collected from the sensor to gain insights into the system’s performance or operating conditions. This may involve plotting graphs, calculating trends, or setting up alerts based on predefined thresholds.

Tips for Reading Data from a Pressure Sensor

Reading data from a pressure sensor can be a complex and challenging task, but with the right approach, it can provide valuable information for various applications. Here are some tips to consider when working with pressure sensors:

- Check the Sensor’s Data Sheet: The sensor’s datasheet contains crucial information about its specifications, pinout, calibration, and connection details. Always refer to the datasheet when setting up or reading data from the sensor.

- Use Proper Signal Conditioning: Depending on the sensor type and output signal, you may need to apply signal conditioning techniques such as amplification, filtering, or linearization to ensure accurate data readings.

- Consider Environmental Factors: Pressure sensors are sensitive to environmental factors such as temperature, humidity, and vibration. Make sure to account for these factors when reading data from the sensor to avoid inaccuracies.

By following these tips and steps, you can effectively read data from a pressure sensor and leverage the information it provides for your specific application or project. Remember to consult the sensor’s datasheet and user manual for accurate setup and calibration instructions to ensure reliable and precise data readings.

Pressure sensors play a crucial role in modern technology, and being able to read data from them accurately is essential for many applications. With the right knowledge and approach, you can harness the power of pressure sensors to monitor and analyze pressure levels effectively.