How to program the UR3 collaborative robot for precision work?

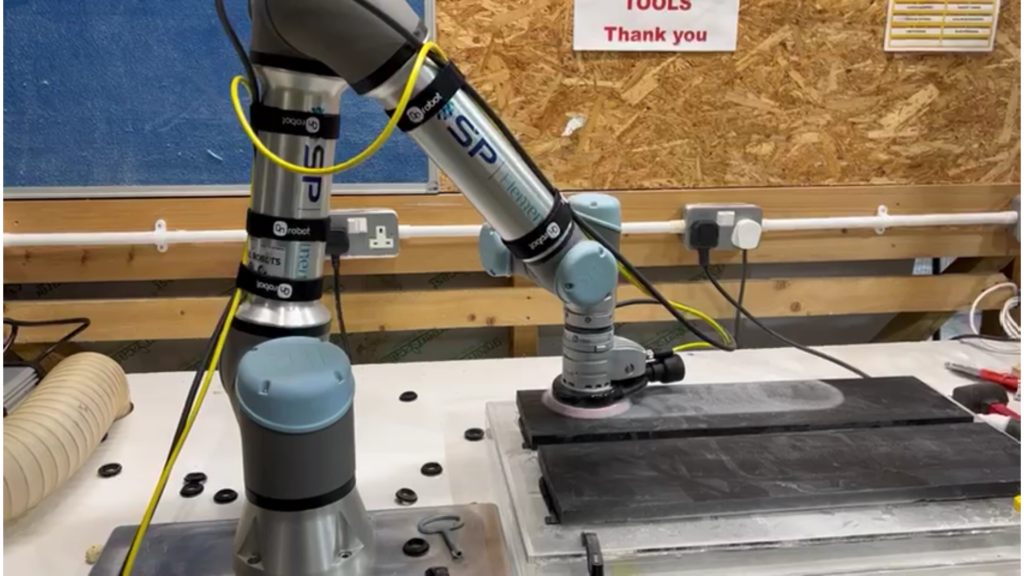

Collaborative robots, also known as cobots, have revolutionized the manufacturing industry. Their ability to work alongside humans in a safe and efficient manner has made them a popular choice for a wide range of applications. The UR3 collaborative robot, with its compact size and precision capabilities, is particularly well-suited for tasks that require high levels of accuracy.

Understanding the UR3 collaborative robot

The UR3 robot is a versatile and lightweight robot that can be easily integrated into a variety of production environments. It is designed to work alongside humans without the need for safety guarding, thanks to its built-in safety features such as force sensing and collision detection.

One of the key features of the UR3 robot is its precision capabilities. With a repeatability of +/- 0.1 mm, it is ideal for tasks that require high levels of accuracy, such as assembly, inspection, and testing.

Programming the UR3 robot for precision work

Programming the UR3 robot for precision work requires a solid understanding of its capabilities and programming interface. Here are some tips to help you get started:

- 1. Familiarize yourself with the UR3 robot’s programming interface, such as the URScript language and the Polyscope software.

- 2. Identify the task that requires precision work and break it down into smaller, manageable steps.

- 3. Use the URScript language to program the robot to perform each step with the desired level of accuracy.

- 4. Test the program on the UR3 robot to ensure that it meets your precision requirements.

- 5. Fine-tune the program as needed to optimize the robot’s performance.

Keep in mind that programming the UR3 robot for precision work can be a complex task, especially if you are new to robotics programming. Don’t be afraid to seek help from experts or consult the UR3 robot’s technical documentation to aid you in the process.

Benefits of programming the UR3 robot for precision work

Programming the UR3 robot for precision work has numerous benefits, including:

- 1. Increased efficiency: By automating precision tasks, you can save time and reduce the risk of human error.

- 2. Improved quality: The UR3 robot’s high level of accuracy ensures consistent quality in manufacturing processes.

- 3. Cost savings: Automating precision work with the UR3 robot can lead to cost savings in the long run.

- 4. Enhanced safety: By delegating precision tasks to the UR3 robot, you can improve workplace safety for your employees.

- 5. Flexibility: The UR3 robot can be reprogrammed quickly and easily to adapt to changing production needs.

In conclusion, programming the UR3 collaborative robot for precision work can help you optimize your manufacturing processes and achieve greater efficiency and accuracy. By following the tips outlined in this article and leveraging the UR3 robot’s capabilities, you can take your production capabilities to the next level.

How to program the UR3 collaborative robot for precision work?

Collaborative robots, also known as cobots, have revolutionized the manufacturing industry. Their ability to work alongside humans in a safe and efficient manner has made them a popular choice for a wide range of applications. The UR3 collaborative robot, with its compact size and precision capabilities, is particularly well-suited for tasks that require high levels of accuracy.

Understanding the UR3 collaborative robot

The UR3 robot is a versatile and lightweight robot that can be easily integrated into a variety of production environments. It is designed to work alongside humans without the need for safety guarding, thanks to its built-in safety features such as force sensing and collision detection.

One of the key features of the UR3 robot is its precision capabilities. With a repeatability of +/- 0.1 mm, it is ideal for tasks that require high levels of accuracy, such as assembly, inspection, and testing.

Programming the UR3 robot for precision work

Programming the UR3 robot for precision work requires a solid understanding of its capabilities and programming interface. Here are some tips to help you get started:

- 1. Familiarize yourself with the UR3 robot’s programming interface, such as the URScript language and the Polyscope software.

- 2. Identify the task that requires precision work and break it down into smaller, manageable steps.

- 3. Use the URScript language to program the robot to perform each step with the desired level of accuracy.

- 4. Test the program on the UR3 robot to ensure that it meets your precision requirements.

- 5. Fine-tune the program as needed to optimize the robot’s performance.

Keep in mind that programming the UR3 robot for precision work can be a complex task, especially if you are new to robotics programming. Don’t be afraid to seek help from experts or consult the UR3 robot’s technical documentation to aid you in the process.

Benefits of programming the UR3 robot for precision work

Programming the UR3 robot for precision work has numerous benefits, including:

- 1. Increased efficiency: By automating precision tasks, you can save time and reduce the risk of human error.

- 2. Improved quality: The UR3 robot’s high level of accuracy ensures consistent quality in manufacturing processes.

- 3. Cost savings: Automating precision work with the UR3 robot can lead to cost savings in the long run.

- 4. Enhanced safety: By delegating precision tasks to the UR3 robot, you can improve workplace safety for your employees.

- 5. Flexibility: The UR3 robot can be reprogrammed quickly and easily to adapt to changing production needs.

In conclusion, programming the UR3 collaborative robot for precision work can help you optimize your manufacturing processes and achieve greater efficiency and accuracy. By following the tips outlined in this article and leveraging the UR3 robot’s capabilities, you can take your production capabilities to the next level.