How to program a Robot ABB for industrial automation?

Programming a Robot ABB for industrial automation is a crucial skill that can greatly enhance the efficiency and productivity of manufacturing processes. With the advancement of technology, robots have become an integral part of modern factories, carrying out tasks with precision and speed. In this guide, we will explore the steps involved in programming a Robot ABB for industrial automation.

1. Familiarize Yourself with the Robot ABB System

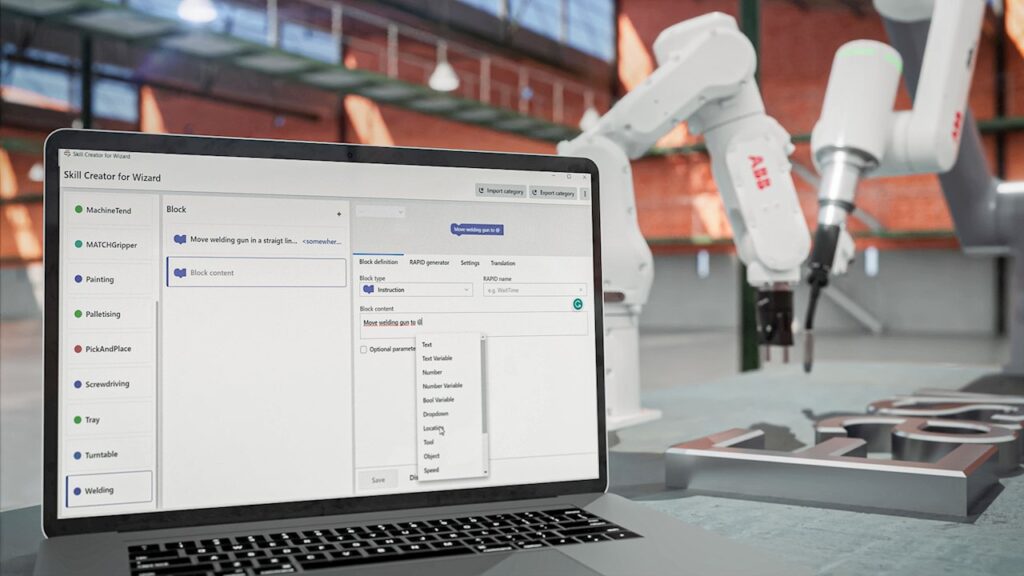

Before you start programming the Robot ABB, it is important to have a good understanding of the system. Familiarize yourself with the hardware components, such as the robot arm, end effector, and controller. Learn about the software interface and programming language used by the Robot ABB system.

2. Create a Task List

Identify the tasks that the robot will be performing in the industrial automation process. Create a detailed task list that outlines the sequence of steps the robot needs to follow. This will help you plan and structure the programming of the Robot ABB system effectively.

3. Write the Program Code

Using the programming language supported by the Robot ABB system, write the program code that defines the robot’s movements and actions. Consider factors such as path planning, collision detection, and end effector control when writing the program code.

4. Test the Program

Once you have written the program code, test it to ensure that the robot performs the tasks accurately and efficiently. Run simulations to identify any errors or issues in the program code and make necessary adjustments.

5. Optimize the Program

Optimize the program code to enhance the performance of the robot in the industrial automation process. Fine-tune the parameters, such as speed, acceleration, and deceleration, to improve the efficiency and accuracy of the robot’s movements.

6. Implement Safety Measures

Ensure that adequate safety measures are in place when programming the Robot ABB for industrial automation. Consider factors such as emergency stop buttons, safety fences, and risk assessments to prevent accidents and ensure the safety of workers in the vicinity.

7. Monitor and Maintain the Robot ABB System

Regularly monitor and maintain the Robot ABB system to ensure its smooth operation in industrial automation processes. Check for wear and tear in the hardware components, update the software, and calibrate the system as needed to maintain optimal performance.

Conclusion

Programming a Robot ABB for industrial automation is a challenging yet rewarding task that requires careful planning and execution. By following the steps outlined in this guide, you can effectively program a Robot ABB system to enhance productivity and efficiency in manufacturing processes.

How to program a Robot ABB for industrial automation?

Programming a Robot ABB for industrial automation is a crucial skill that can greatly enhance the efficiency and productivity of manufacturing processes. With the advancement of technology, robots have become an integral part of modern factories, carrying out tasks with precision and speed. In this guide, we will explore the steps involved in programming a Robot ABB for industrial automation.

1. Familiarize Yourself with the Robot ABB System

Before you start programming the Robot ABB, it is important to have a good understanding of the system. Familiarize yourself with the hardware components, such as the robot arm, end effector, and controller. Learn about the software interface and programming language used by the Robot ABB system.

2. Create a Task List

Identify the tasks that the robot will be performing in the industrial automation process. Create a detailed task list that outlines the sequence of steps the robot needs to follow. This will help you plan and structure the programming of the Robot ABB system effectively.

3. Write the Program Code

Using the programming language supported by the Robot ABB system, write the program code that defines the robot’s movements and actions. Consider factors such as path planning, collision detection, and end effector control when writing the program code.

4. Test the Program

Once you have written the program code, test it to ensure that the robot performs the tasks accurately and efficiently. Run simulations to identify any errors or issues in the program code and make necessary adjustments.

5. Optimize the Program

Optimize the program code to enhance the performance of the robot in the industrial automation process. Fine-tune the parameters, such as speed, acceleration, and deceleration, to improve the efficiency and accuracy of the robot’s movements.

6. Implement Safety Measures

Ensure that adequate safety measures are in place when programming the Robot ABB for industrial automation. Consider factors such as emergency stop buttons, safety fences, and risk assessments to prevent accidents and ensure the safety of workers in the vicinity.

7. Monitor and Maintain the Robot ABB System

Regularly monitor and maintain the Robot ABB system to ensure its smooth operation in industrial automation processes. Check for wear and tear in the hardware components, update the software, and calibrate the system as needed to maintain optimal performance.

Conclusion

Programming a Robot ABB for industrial automation is a challenging yet rewarding task that requires careful planning and execution. By following the steps outlined in this guide, you can effectively program a Robot ABB system to enhance productivity and efficiency in manufacturing processes.