How to Program a Pick and Place Robot for Industrial Tasks

Programming a pick and place robot for industrial tasks requires careful planning and execution to ensure optimal performance and efficiency. Whether you are new to robotics programming or looking to improve your existing skills, this article will provide step-by-step guidance on how to effectively program a pick and place robot for various industrial tasks.

Understanding the Basics

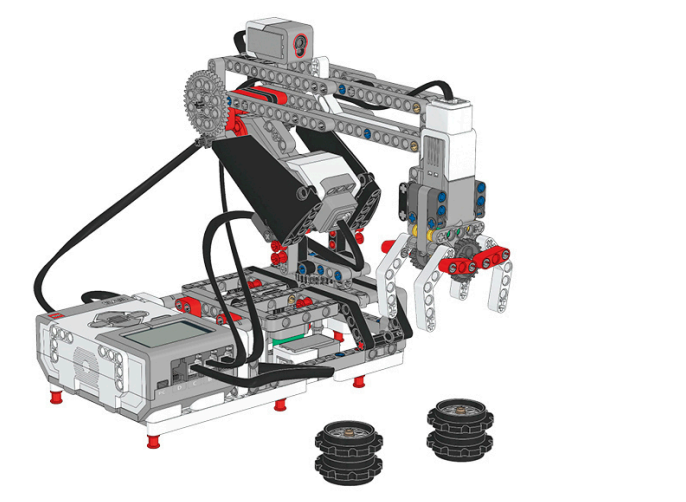

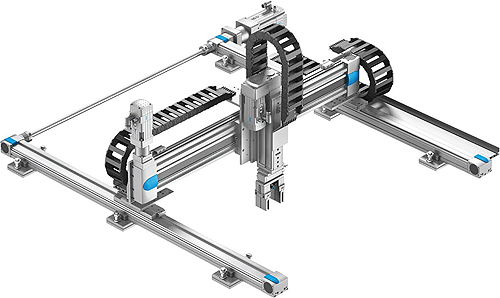

Before diving into the programming process, it is essential to understand the basic components and functionalities of a pick and place robot. A pick and place robot is a type of industrial robot that is designed to move items from one location to another with precision and accuracy. These robots are commonly used in manufacturing and assembly processes to automate repetitive tasks and improve productivity.

Key components of a pick and place robot include:

- Manipulator arm: The arm of the robot that is responsible for picking up and placing items

- End effector: The tool attached to the end of the manipulator arm, such as a gripper or suction cup

- Sensors: Devices that enable the robot to detect and respond to its environment

- Controller: The brain of the robot that processes data and sends commands to the manipulator arm

Programming Steps

Now that you have a basic understanding of the pick and place robot, let’s dive into the programming steps:

- Define the task: The first step in programming a pick and place robot is to clearly define the task that the robot will be performing. This includes identifying the items to be picked up and placed, as well as the specific locations for the placement.

- Choose the appropriate programming language: Pick and place robots can be programmed using various programming languages, such as C++, Python, or ROS (Robot Operating System). Choose a language that is compatible with your robot and programming environment.

- Develop the motion logic: Create a set of instructions for the robot to follow in order to complete the task. This includes defining the sequence of movements for picking up and placing items, as well as any additional actions required during the process.

- Integrate sensor feedback: Utilize sensor data to ensure precise and accurate movements. Sensors can provide valuable feedback to the robot, such as detecting the presence of an item or measuring the distance to a target location.

- Test and optimize: Once the program has been developed, test it in a controlled environment to ensure that the robot performs as expected. Make any necessary adjustments to optimize the program for efficiency and reliability.

Best Practices

To maximize the performance of your pick and place robot, consider the following best practices:

- Optimize motion paths to minimize cycle time

- Utilize vision systems for object detection and alignment

- Implement error handling mechanisms to address unexpected situations

- Regularly maintain and calibrate the robot to ensure consistent performance

By following these steps and best practices, you can effectively program a pick and place robot for a wide range of industrial tasks. Remember to continuously monitor and improve your programming skills to keep pace with advancements in robotics technology.

How to Program a Pick and Place Robot for Industrial Tasks

Programming a pick and place robot for industrial tasks requires careful planning and execution to ensure optimal performance and efficiency. Whether you are new to robotics programming or looking to improve your existing skills, this article will provide step-by-step guidance on how to effectively program a pick and place robot for various industrial tasks.

Understanding the Basics

Before diving into the programming process, it is essential to understand the basic components and functionalities of a pick and place robot. A pick and place robot is a type of industrial robot that is designed to move items from one location to another with precision and accuracy. These robots are commonly used in manufacturing and assembly processes to automate repetitive tasks and improve productivity.

Key components of a pick and place robot include:

- Manipulator arm: The arm of the robot that is responsible for picking up and placing items

- End effector: The tool attached to the end of the manipulator arm, such as a gripper or suction cup

- Sensors: Devices that enable the robot to detect and respond to its environment

- Controller: The brain of the robot that processes data and sends commands to the manipulator arm

Programming Steps

Now that you have a basic understanding of the pick and place robot, let’s dive into the programming steps:

- Define the task: The first step in programming a pick and place robot is to clearly define the task that the robot will be performing. This includes identifying the items to be picked up and placed, as well as the specific locations for the placement.

- Choose the appropriate programming language: Pick and place robots can be programmed using various programming languages, such as C++, Python, or ROS (Robot Operating System). Choose a language that is compatible with your robot and programming environment.

- Develop the motion logic: Create a set of instructions for the robot to follow in order to complete the task. This includes defining the sequence of movements for picking up and placing items, as well as any additional actions required during the process.

- Integrate sensor feedback: Utilize sensor data to ensure precise and accurate movements. Sensors can provide valuable feedback to the robot, such as detecting the presence of an item or measuring the distance to a target location.

- Test and optimize: Once the program has been developed, test it in a controlled environment to ensure that the robot performs as expected. Make any necessary adjustments to optimize the program for efficiency and reliability.

Best Practices

To maximize the performance of your pick and place robot, consider the following best practices:

- Optimize motion paths to minimize cycle time

- Utilize vision systems for object detection and alignment

- Implement error handling mechanisms to address unexpected situations

- Regularly maintain and calibrate the robot to ensure consistent performance

By following these steps and best practices, you can effectively program a pick and place robot for a wide range of industrial tasks. Remember to continuously monitor and improve your programming skills to keep pace with advancements in robotics technology.