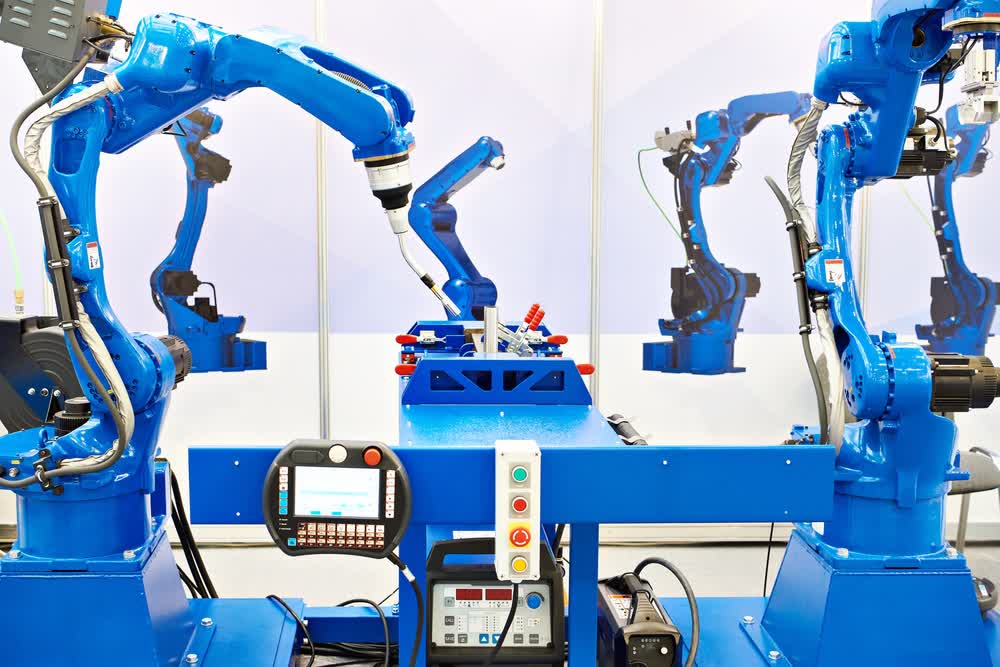

How to program a 6‑axis robot for industrial applications?

Programming a 6-axis robot for industrial applications can seem like a daunting task, but with the right approach and tools, it can be straightforward and rewarding. In this guide, we will walk you through the steps of programming a 6-axis robot for various industrial applications.

Step 1: Understand the Robot

Before you start programming the robot, it is essential to understand the robot’s capabilities and limitations. A 6-axis robot can move in six different directions, making it versatile and suitable for a wide range of tasks. Make sure to familiarize yourself with the robot’s manual and specifications before proceeding.

Step 2: Choose the Right Programming Language

There are several programming languages that you can use to program a 6-axis robot, such as RoboDK, ROS, or G-code. Choose the programming language that is best suited for your application and is supported by the robot’s controller.

Step 3: Set Up the Programming Environment

Once you have chosen the programming language, set up the programming environment by installing the necessary software and connecting it to the robot’s controller. Make sure that you have access to the robot’s teach pendant or a simulation environment to test your programs.

Step 4: Write and Test the Program

Now it’s time to write the program for the 6-axis robot. Start by defining the robot’s movements, such as picking up an object, moving it to a different location, and placing it down. Test the program in the simulation environment or using the teach pendant to ensure that it works as intended.

Step 5: Optimize and Refine the Program

Once you have tested the program, optimize and refine it to improve the robot’s performance and efficiency. Make adjustments to the code, such as adjusting the speed and acceleration of the robot’s movements, to optimize its operation.

Step 6: Deploy the Program in a Real-World Setting

After you have optimized the program, deploy it in a real-world setting to test its performance in an industrial application. Monitor the robot’s movements and make any necessary adjustments to ensure that it operates smoothly and efficiently.

Conclusion

Programming a 6-axis robot for industrial applications can be a challenging but rewarding process. By following the steps outlined in this guide and taking the time to understand the robot’s capabilities, you can successfully program a 6-axis robot for a wide range of industrial tasks. Remember to test and refine your programs to optimize the robot’s performance and efficiency in real-world settings.

How to program a 6‑axis robot for industrial applications?

Programming a 6-axis robot for industrial applications can seem like a daunting task, but with the right approach and tools, it can be straightforward and rewarding. In this guide, we will walk you through the steps of programming a 6-axis robot for various industrial applications.

Step 1: Understand the Robot

Before you start programming the robot, it is essential to understand the robot’s capabilities and limitations. A 6-axis robot can move in six different directions, making it versatile and suitable for a wide range of tasks. Make sure to familiarize yourself with the robot’s manual and specifications before proceeding.

Step 2: Choose the Right Programming Language

There are several programming languages that you can use to program a 6-axis robot, such as RoboDK, ROS, or G-code. Choose the programming language that is best suited for your application and is supported by the robot’s controller.

Step 3: Set Up the Programming Environment

Once you have chosen the programming language, set up the programming environment by installing the necessary software and connecting it to the robot’s controller. Make sure that you have access to the robot’s teach pendant or a simulation environment to test your programs.

Step 4: Write and Test the Program

Now it’s time to write the program for the 6-axis robot. Start by defining the robot’s movements, such as picking up an object, moving it to a different location, and placing it down. Test the program in the simulation environment or using the teach pendant to ensure that it works as intended.

Step 5: Optimize and Refine the Program

Once you have tested the program, optimize and refine it to improve the robot’s performance and efficiency. Make adjustments to the code, such as adjusting the speed and acceleration of the robot’s movements, to optimize its operation.

Step 6: Deploy the Program in a Real-World Setting

After you have optimized the program, deploy it in a real-world setting to test its performance in an industrial application. Monitor the robot’s movements and make any necessary adjustments to ensure that it operates smoothly and efficiently.

Conclusion

Programming a 6-axis robot for industrial applications can be a challenging but rewarding process. By following the steps outlined in this guide and taking the time to understand the robot’s capabilities, you can successfully program a 6-axis robot for a wide range of industrial tasks. Remember to test and refine your programs to optimize the robot’s performance and efficiency in real-world settings.