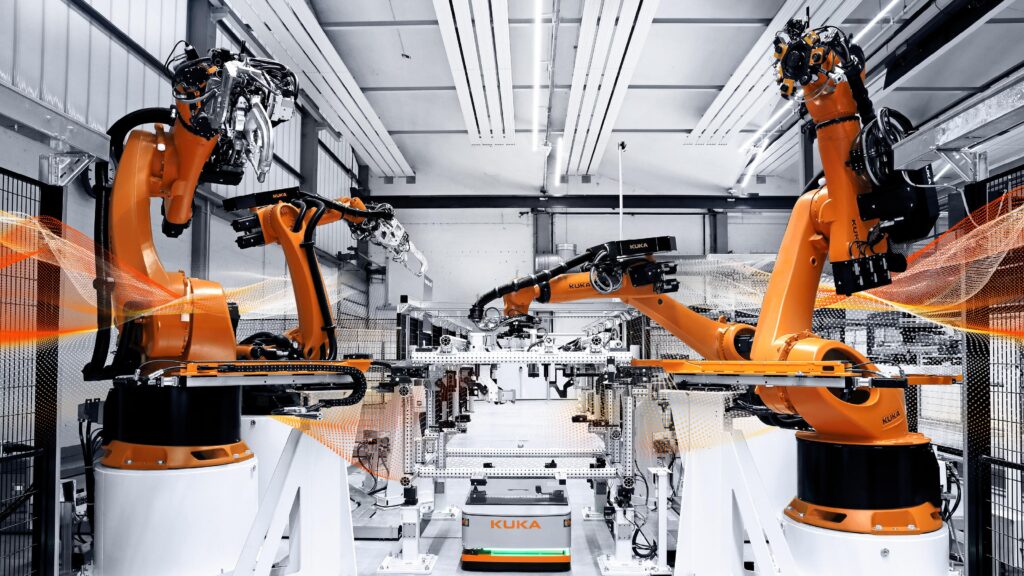

How to operate a KUKA robot arm for industrial tasks?

Operating a KUKA robot arm for industrial tasks can be a daunting task, but with the right knowledge and skills, you can effectively utilize this advanced technology to streamline your manufacturing processes. In this guide, we will walk you through the key steps and best practices for operating a KUKA robot arm in an industrial setting.

Step 1: Familiarize Yourself with the KUKA Robot Arm

Before you start operating the KUKA robot arm, it is essential to familiarize yourself with its components and functionalities. The KUKA robot arm consists of various parts, including the arm itself, end effector, and controller. Take the time to study the user manual and understand how each component works together to perform tasks efficiently.

Step 2: Programming the KUKA Robot Arm

Programming the KUKA robot arm is an essential step in operating it for industrial tasks. The robot arm can be programmed using a computer with specialized software. You can create programs for different tasks, such as pick and place, welding, or assembly. Make sure to thoroughly test and debug your programs before executing them on the robot arm.

Step 3: Safety First

Safety should always be a top priority when operating a KUKA robot arm. Make sure to follow all safety protocols provided by the manufacturer and ensure that the work area is clear of any obstructions. It is also essential to wear appropriate personal protective equipment while operating the robot arm to prevent any accidents or injuries.

Step 4: Calibration and Testing

Before using the KUKA robot arm for industrial tasks, it is crucial to calibrate and test the robot arm to ensure its accuracy and precision. Perform calibration checks regularly to maintain the robot arm’s performance and make any necessary adjustments to improve its efficiency.

Step 5: Monitoring and Maintenance

Once you have successfully operated the KUKA robot arm for industrial tasks, it is essential to monitor its performance and conduct regular maintenance to prevent any breakdowns or malfunctions. Keep track of the robot arm’s usage and schedule routine maintenance checks to ensure its longevity and reliability.

Conclusion

Operating a KUKA robot arm for industrial tasks requires a combination of skills, knowledge, and attention to detail. By following the steps outlined in this guide and staying vigilant about safety and maintenance, you can effectively utilize the KUKA robot arm to enhance your manufacturing processes and increase productivity.

How to operate a KUKA robot arm for industrial tasks?

Operating a KUKA robot arm for industrial tasks can be a daunting task, but with the right knowledge and skills, you can effectively utilize this advanced technology to streamline your manufacturing processes. In this guide, we will walk you through the key steps and best practices for operating a KUKA robot arm in an industrial setting.

Step 1: Familiarize Yourself with the KUKA Robot Arm

Before you start operating the KUKA robot arm, it is essential to familiarize yourself with its components and functionalities. The KUKA robot arm consists of various parts, including the arm itself, end effector, and controller. Take the time to study the user manual and understand how each component works together to perform tasks efficiently.

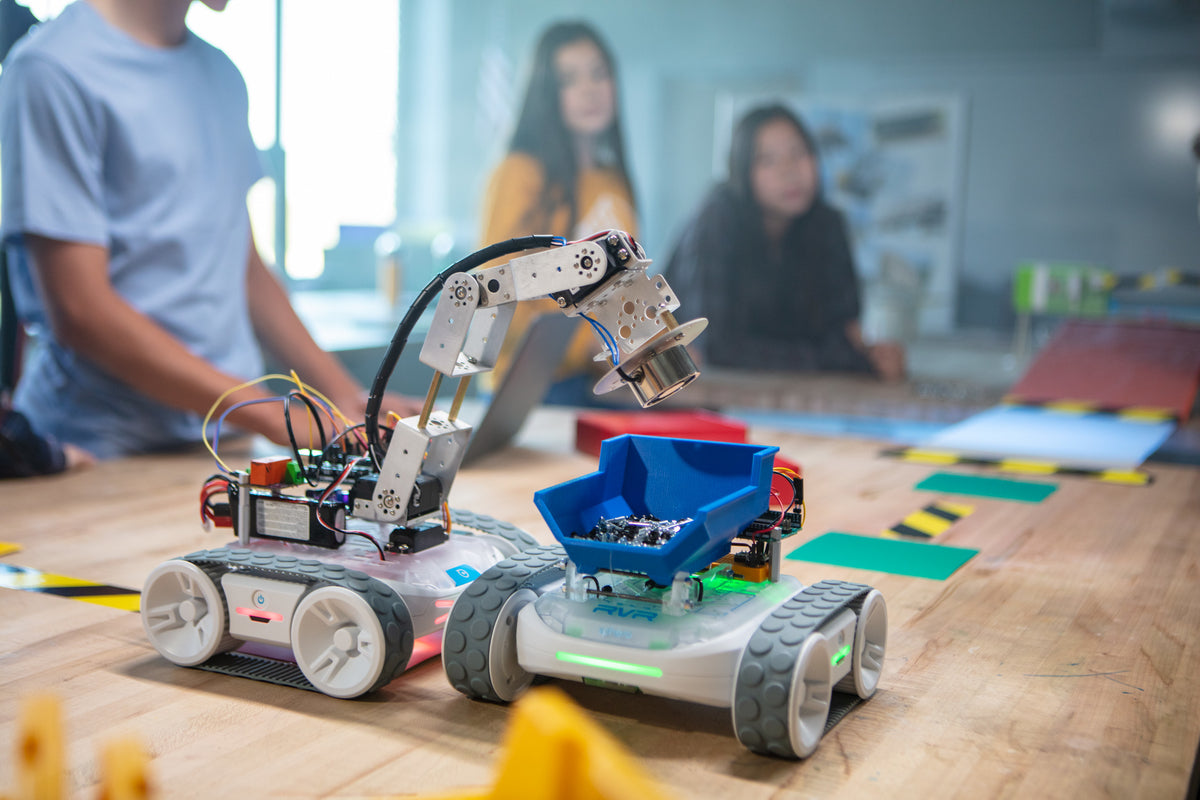

Step 2: Programming the KUKA Robot Arm

Programming the KUKA robot arm is an essential step in operating it for industrial tasks. The robot arm can be programmed using a computer with specialized software. You can create programs for different tasks, such as pick and place, welding, or assembly. Make sure to thoroughly test and debug your programs before executing them on the robot arm.

Step 3: Safety First

Safety should always be a top priority when operating a KUKA robot arm. Make sure to follow all safety protocols provided by the manufacturer and ensure that the work area is clear of any obstructions. It is also essential to wear appropriate personal protective equipment while operating the robot arm to prevent any accidents or injuries.

Step 4: Calibration and Testing

Before using the KUKA robot arm for industrial tasks, it is crucial to calibrate and test the robot arm to ensure its accuracy and precision. Perform calibration checks regularly to maintain the robot arm’s performance and make any necessary adjustments to improve its efficiency.

Step 5: Monitoring and Maintenance

Once you have successfully operated the KUKA robot arm for industrial tasks, it is essential to monitor its performance and conduct regular maintenance to prevent any breakdowns or malfunctions. Keep track of the robot arm’s usage and schedule routine maintenance checks to ensure its longevity and reliability.

Conclusion

Operating a KUKA robot arm for industrial tasks requires a combination of skills, knowledge, and attention to detail. By following the steps outlined in this guide and staying vigilant about safety and maintenance, you can effectively utilize the KUKA robot arm to enhance your manufacturing processes and increase productivity.