How to Measure Torque with a Strain Gauge

When it comes to measuring torque, a strain gauge is an essential tool. Torque is the force that causes an object to rotate around an axis, and it is a crucial factor in many mechanical systems. By using a strain gauge, you can accurately measure the torque applied to an object, whether it’s a machine part, a vehicle component, or any other piece of equipment.

So, how exactly do you measure torque with a strain gauge? In this article, we will walk you through the steps and provide you with all the information you need to get started.

What is a Strain Gauge?

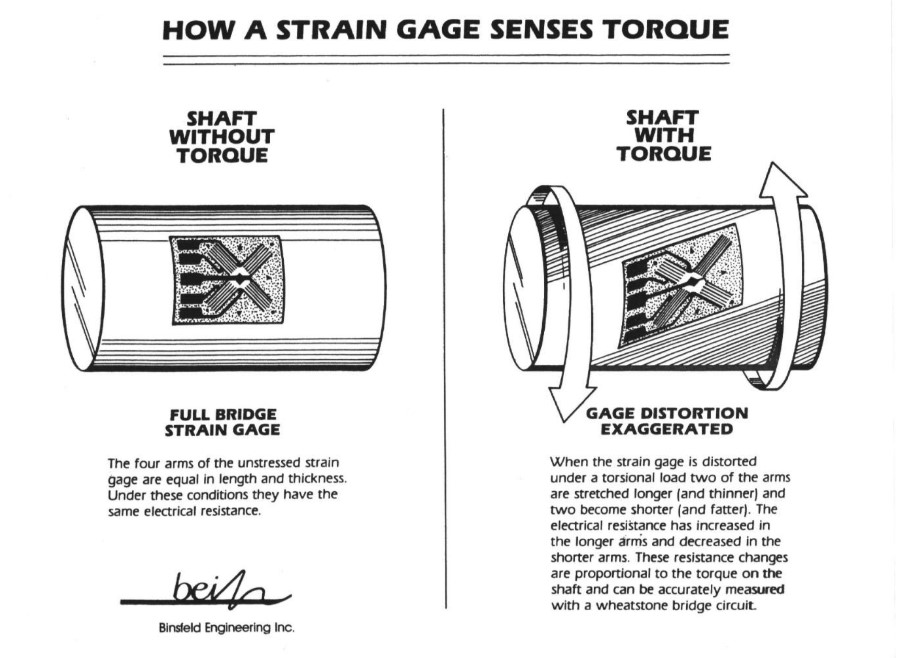

Before we dive into the process of measuring torque with a strain gauge, let’s first understand what a strain gauge is. A strain gauge is a device that measures the strain, or deformation, of an object. It works on the principle that the electrical resistance of a metal changes when it is stretched or compressed.

Strain gauges are often used in applications where it is necessary to measure the stress and strain on a material, such as in mechanical testing, structural monitoring, and torque measurement.

Measuring Torque with a Strain Gauge

To measure torque with a strain gauge, you will need to follow these steps:

- Attach the strain gauge to the surface of the object where you want to measure the torque. Make sure it is securely attached and aligned properly.

- Apply a known force, or torque, to the object. This will cause the object to deform, and the strain gauge will measure the resulting strain.

- Calibrate the strain gauge to ensure accurate measurements. This may involve applying known forces to the object and adjusting the gauge readings accordingly.

- Measure the electrical resistance changes in the strain gauge. These changes can be correlated with the torque applied to the object.

- Calculate the torque based on the strain gauge readings and any calibration data.

It is important to note that measuring torque with a strain gauge requires precision and accuracy. Proper calibration and alignment of the strain gauge are essential to obtaining reliable measurements.

Applications of Torque Measurement with Strain Gauges

Measuring torque with strain gauges has various applications in different industries. Some common uses include:

- Automotive industry: Torque measurement in engines, transmissions, and driveline components.

- Aerospace industry: Torque measurement in aircraft components and structures.

- Manufacturing: Torque measurement in machinery and equipment.

- Research and development: Torque measurement in testing and experimental setups.

By using strain gauges to measure torque, engineers and technicians can ensure the safety, efficiency, and performance of various mechanical systems.

Conclusion

Measuring torque with a strain gauge is a valuable technique that provides valuable insights into the performance of mechanical systems. By following the steps outlined in this article and ensuring proper calibration and alignment, you can accurately measure torque and optimize the operation of equipment in various industries.

Whether you are working in automotive, aerospace, manufacturing, or research and development, torque measurement with strain gauges can help you achieve your goals and improve the efficiency of your processes.

How to Measure Torque with a Strain Gauge

When it comes to measuring torque, a strain gauge is an essential tool. Torque is the force that causes an object to rotate around an axis, and it is a crucial factor in many mechanical systems. By using a strain gauge, you can accurately measure the torque applied to an object, whether it’s a machine part, a vehicle component, or any other piece of equipment.

So, how exactly do you measure torque with a strain gauge? In this article, we will walk you through the steps and provide you with all the information you need to get started.

What is a Strain Gauge?

Before we dive into the process of measuring torque with a strain gauge, let’s first understand what a strain gauge is. A strain gauge is a device that measures the strain, or deformation, of an object. It works on the principle that the electrical resistance of a metal changes when it is stretched or compressed.

Strain gauges are often used in applications where it is necessary to measure the stress and strain on a material, such as in mechanical testing, structural monitoring, and torque measurement.

Measuring Torque with a Strain Gauge

To measure torque with a strain gauge, you will need to follow these steps:

- Attach the strain gauge to the surface of the object where you want to measure the torque. Make sure it is securely attached and aligned properly.

- Apply a known force, or torque, to the object. This will cause the object to deform, and the strain gauge will measure the resulting strain.

- Calibrate the strain gauge to ensure accurate measurements. This may involve applying known forces to the object and adjusting the gauge readings accordingly.

- Measure the electrical resistance changes in the strain gauge. These changes can be correlated with the torque applied to the object.

- Calculate the torque based on the strain gauge readings and any calibration data.

It is important to note that measuring torque with a strain gauge requires precision and accuracy. Proper calibration and alignment of the strain gauge are essential to obtaining reliable measurements.

Applications of Torque Measurement with Strain Gauges

Measuring torque with strain gauges has various applications in different industries. Some common uses include:

- Automotive industry: Torque measurement in engines, transmissions, and driveline components.

- Aerospace industry: Torque measurement in aircraft components and structures.

- Manufacturing: Torque measurement in machinery and equipment.

- Research and development: Torque measurement in testing and experimental setups.

By using strain gauges to measure torque, engineers and technicians can ensure the safety, efficiency, and performance of various mechanical systems.

Conclusion

Measuring torque with a strain gauge is a valuable technique that provides valuable insights into the performance of mechanical systems. By following the steps outlined in this article and ensuring proper calibration and alignment, you can accurately measure torque and optimize the operation of equipment in various industries.

Whether you are working in automotive, aerospace, manufacturing, or research and development, torque measurement with strain gauges can help you achieve your goals and improve the efficiency of your processes.