How to Integrate a Gantry Robot into Industrial Workflows?

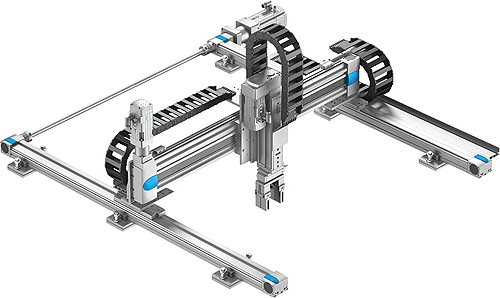

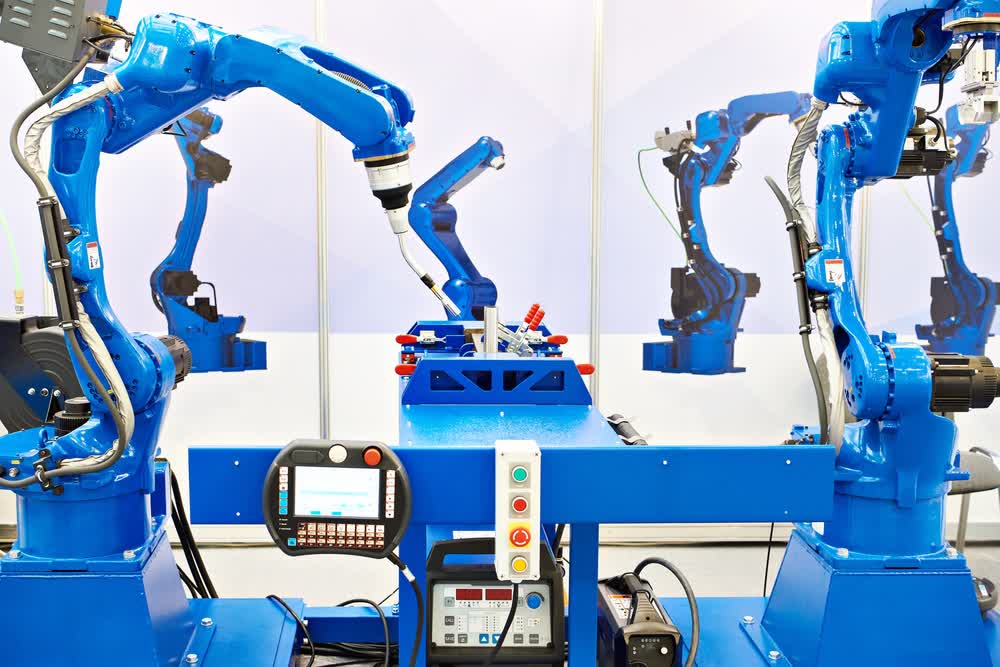

Gantry robots are versatile machines that are increasingly being used in various industries to streamline processes and increase productivity. These robots, also known as Cartesian or linear robots, are capable of performing a wide range of tasks with precision and speed. Integrating a gantry robot into your industrial workflows can help you automate repetitive tasks, improve accuracy, and reduce costs.

Choose the Right Gantry Robot

Before integrating a gantry robot into your industrial workflows, it is important to choose the right robot for your specific application. Consider factors such as payload capacity, reach, speed, and precision requirements. It is also important to consider the available space in your facility and how the robot will fit into your existing workflow.

Design a Seamless Integration Process

Once you have selected the right gantry robot for your needs, it is important to design a seamless integration process. This process should involve planning the placement of the robot within your facility, integrating it with existing machinery, and programming it to perform the required tasks. Make sure to work closely with the robot manufacturer or an experienced integrator to ensure a smooth integration process.

Train Your Employees

Integrating a gantry robot into your industrial workflows may require some training for your employees. Make sure that your team is familiar with the operation of the robot and understands how to program it for different tasks. Training your employees will help ensure that the robot is used effectively and efficiently in your facility.

Monitor Performance and Make Adjustments

Once the gantry robot is integrated into your industrial workflows, it is important to monitor its performance regularly. Keep track of key performance indicators such as cycle time, throughput, and error rates. If you notice any issues or inefficiencies, make adjustments to the robot’s programming or workflow to optimize its performance.

Benefits of Integrating a Gantry Robot

- Increased efficiency: Gantry robots can perform tasks with speed and precision, leading to increased efficiency in your workflows.

- Reduced costs: Automating repetitive tasks with a gantry robot can help reduce labor costs and improve overall productivity.

- Improved accuracy: Gantry robots are capable of performing tasks with high accuracy, reducing the likelihood of errors in your processes.

- Flexibility: Gantry robots can be programmed to perform a wide range of tasks, making them versatile machines for various industrial applications.

By following these steps and integrating a gantry robot into your industrial workflows, you can improve efficiency, reduce costs, and enhance overall productivity in your facility.

How to Integrate a Gantry Robot into Industrial Workflows?

Gantry robots are versatile machines that are increasingly being used in various industries to streamline processes and increase productivity. These robots, also known as Cartesian or linear robots, are capable of performing a wide range of tasks with precision and speed. Integrating a gantry robot into your industrial workflows can help you automate repetitive tasks, improve accuracy, and reduce costs.

Choose the Right Gantry Robot

Before integrating a gantry robot into your industrial workflows, it is important to choose the right robot for your specific application. Consider factors such as payload capacity, reach, speed, and precision requirements. It is also important to consider the available space in your facility and how the robot will fit into your existing workflow.

Design a Seamless Integration Process

Once you have selected the right gantry robot for your needs, it is important to design a seamless integration process. This process should involve planning the placement of the robot within your facility, integrating it with existing machinery, and programming it to perform the required tasks. Make sure to work closely with the robot manufacturer or an experienced integrator to ensure a smooth integration process.

Train Your Employees

Integrating a gantry robot into your industrial workflows may require some training for your employees. Make sure that your team is familiar with the operation of the robot and understands how to program it for different tasks. Training your employees will help ensure that the robot is used effectively and efficiently in your facility.

Monitor Performance and Make Adjustments

Once the gantry robot is integrated into your industrial workflows, it is important to monitor its performance regularly. Keep track of key performance indicators such as cycle time, throughput, and error rates. If you notice any issues or inefficiencies, make adjustments to the robot’s programming or workflow to optimize its performance.

Benefits of Integrating a Gantry Robot

- Increased efficiency: Gantry robots can perform tasks with speed and precision, leading to increased efficiency in your workflows.

- Reduced costs: Automating repetitive tasks with a gantry robot can help reduce labor costs and improve overall productivity.

- Improved accuracy: Gantry robots are capable of performing tasks with high accuracy, reducing the likelihood of errors in your processes.

- Flexibility: Gantry robots can be programmed to perform a wide range of tasks, making them versatile machines for various industrial applications.

By following these steps and integrating a gantry robot into your industrial workflows, you can improve efficiency, reduce costs, and enhance overall productivity in your facility.