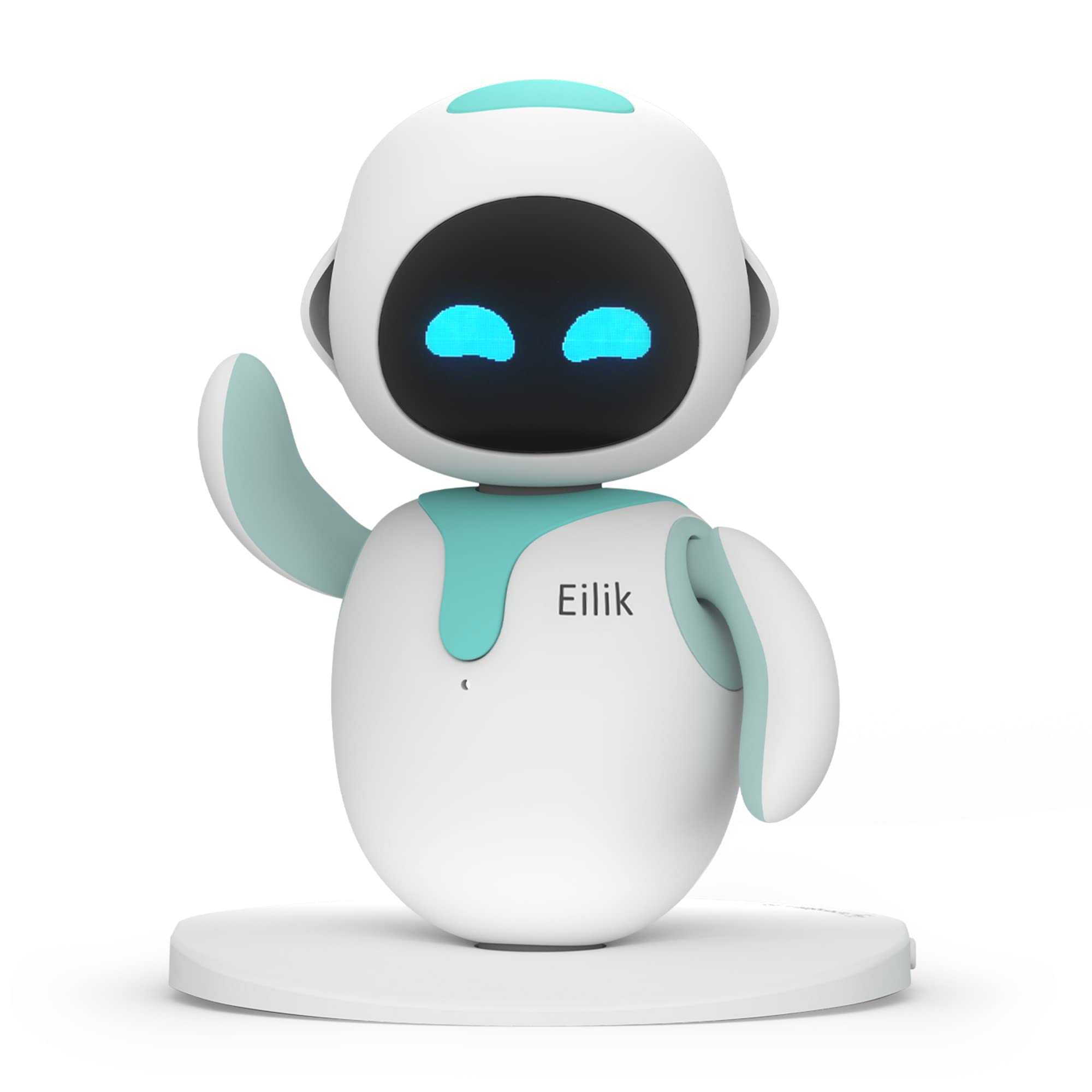

How to implement robot vision for advanced automation?

In the realm of automation, the integration of robot vision has become increasingly essential. By providing robots with the ability to ‘see’, businesses can achieve new levels of efficiency and precision in their manufacturing processes. In this article, we will explore the key steps to successfully implement robot vision for advanced automation.

Step 1: Define your objectives

Before delving into the technical aspects of robot vision, it is crucial to define the specific objectives you aim to achieve. Whether it’s improving quality control, enhancing productivity, or streamlining logistics, having clear goals will guide your implementation process.

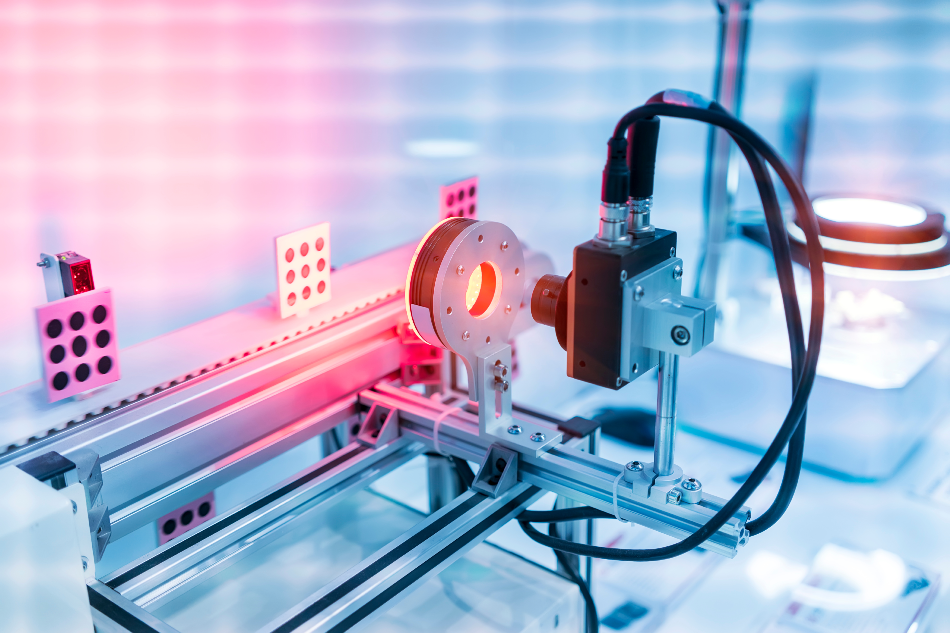

Step 2: Select the right hardware

Choosing the appropriate hardware is paramount in ensuring the success of your robot vision system. Factors such as camera resolution, frame rate, and field of view must be carefully considered to meet the requirements of your automation project.

Step 3: Develop your software

Once the hardware is in place, the next step is to develop the software that will enable your robot to interpret visual data. This may involve using machine learning algorithms, image processing techniques, or specialized vision libraries to analyze and make decisions based on the images captured.

Step 4: Integrate with your automation system

Seamless integration is key to the successful deployment of robot vision in your automation environment. Ensure that your vision system can communicate effectively with other components of your automation system, such as robotic arms, conveyors, or PLCs.

Step 5: Test and optimize

Testing is a critical phase in implementing robot vision for advanced automation. Conduct thorough testing to evaluate the performance of your vision system under different conditions and continuously optimize the algorithms to improve accuracy and efficiency.

Step 6: Monitor and maintain

Once your robot vision system is up and running, it is essential to establish monitoring procedures to ensure its continued functionality. Regular maintenance and calibration of the hardware and software components will help prevent downtime and maintain optimal performance.

Conclusion

By following these steps and integrating robot vision into your automation processes, you can unlock a new realm of possibilities for your business. From increased productivity to enhanced quality control, the benefits of robot vision are vast and can revolutionize the way you approach automation.

How to implement robot vision for advanced automation?

In the realm of automation, the integration of robot vision has become increasingly essential. By providing robots with the ability to ‘see’, businesses can achieve new levels of efficiency and precision in their manufacturing processes. In this article, we will explore the key steps to successfully implement robot vision for advanced automation.

Step 1: Define your objectives

Before delving into the technical aspects of robot vision, it is crucial to define the specific objectives you aim to achieve. Whether it’s improving quality control, enhancing productivity, or streamlining logistics, having clear goals will guide your implementation process.

Step 2: Select the right hardware

Choosing the appropriate hardware is paramount in ensuring the success of your robot vision system. Factors such as camera resolution, frame rate, and field of view must be carefully considered to meet the requirements of your automation project.

Step 3: Develop your software

Once the hardware is in place, the next step is to develop the software that will enable your robot to interpret visual data. This may involve using machine learning algorithms, image processing techniques, or specialized vision libraries to analyze and make decisions based on the images captured.

Step 4: Integrate with your automation system

Seamless integration is key to the successful deployment of robot vision in your automation environment. Ensure that your vision system can communicate effectively with other components of your automation system, such as robotic arms, conveyors, or PLCs.

Step 5: Test and optimize

Testing is a critical phase in implementing robot vision for advanced automation. Conduct thorough testing to evaluate the performance of your vision system under different conditions and continuously optimize the algorithms to improve accuracy and efficiency.

Step 6: Monitor and maintain

Once your robot vision system is up and running, it is essential to establish monitoring procedures to ensure its continued functionality. Regular maintenance and calibration of the hardware and software components will help prevent downtime and maintain optimal performance.

Conclusion

By following these steps and integrating robot vision into your automation processes, you can unlock a new realm of possibilities for your business. From increased productivity to enhanced quality control, the benefits of robot vision are vast and can revolutionize the way you approach automation.