How to Implement AGV Robot Solutions for Logistics

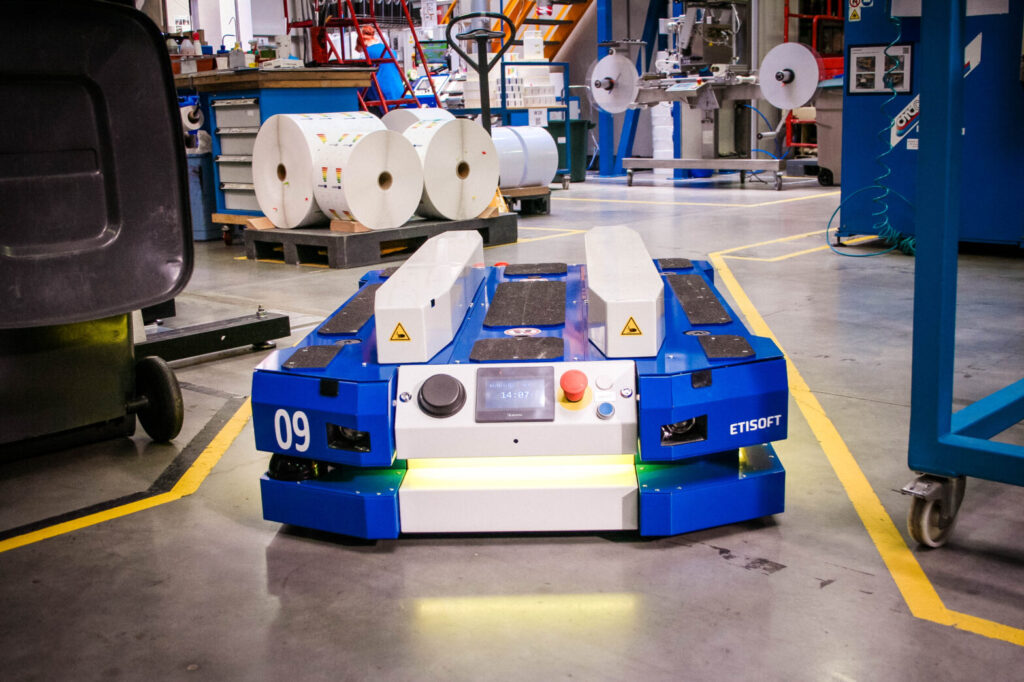

AGV (Automated Guided Vehicle) robots have revolutionized the way logistics companies handle material handling tasks in warehouses and distribution centers. These robotic solutions can significantly improve efficiency, productivity, and safety in logistics operations. However, implementing AGV robots successfully requires careful planning and execution. In this article, we will discuss the steps involved in implementing AGV robot solutions for logistics.

Step 1: Assess Your Needs

The first step in implementing AGV robot solutions is to assess your current material handling processes and identify areas where AGV robots can be beneficial. Consider factors such as the volume of materials handled, the layout of your warehouse, and the types of tasks that can be automated with AGV robots.

Step 2: Choose the Right AGV Robot

Once you have identified the areas where AGV robots can be useful, it is important to choose the right AGV robot for your specific needs. Consider factors such as payload capacity, speed, navigation capabilities, and integration with existing systems.

Step 3: Plan the Implementation

Before deploying AGV robots in your logistics operations, it is essential to plan the implementation carefully. This includes designing the robot paths, setting up charging stations, and integrating the robots with your warehouse management system.

Step 4: Train Your Staff

Training your staff on how to work with AGV robots is crucial for a successful implementation. Make sure your employees are familiar with the robots’ operation, safety protocols, and maintenance procedures.

Step 5: Monitor and Optimize

Once the AGV robots are deployed in your logistics operations, it is important to monitor their performance and optimize their operation continuously. Use data analytics to identify areas for improvement and make adjustments as needed.

Benefits of AGV Robot Solutions

- Increased Efficiency: AGV robots can handle material handling tasks faster and more accurately than manual labor.

- Cost Savings: By automating repetitive tasks, AGV robots can reduce labor costs and increase productivity.

- Improved Safety: AGV robots can work alongside human employees in a warehouse without posing a safety risk.

- Flexibility: AGV robots can be easily reprogrammed to adapt to changing logistics needs.

Overall, implementing AGV robot solutions for logistics can bring numerous benefits to your warehouse operations. By following the steps outlined in this article and carefully planning the implementation, you can streamline your material handling processes, increase efficiency, and stay ahead of the competition in the logistics industry.

How to Implement AGV Robot Solutions for Logistics

AGV (Automated Guided Vehicle) robots have revolutionized the way logistics companies handle material handling tasks in warehouses and distribution centers. These robotic solutions can significantly improve efficiency, productivity, and safety in logistics operations. However, implementing AGV robots successfully requires careful planning and execution. In this article, we will discuss the steps involved in implementing AGV robot solutions for logistics.

Step 1: Assess Your Needs

The first step in implementing AGV robot solutions is to assess your current material handling processes and identify areas where AGV robots can be beneficial. Consider factors such as the volume of materials handled, the layout of your warehouse, and the types of tasks that can be automated with AGV robots.

Step 2: Choose the Right AGV Robot

Once you have identified the areas where AGV robots can be useful, it is important to choose the right AGV robot for your specific needs. Consider factors such as payload capacity, speed, navigation capabilities, and integration with existing systems.

Step 3: Plan the Implementation

Before deploying AGV robots in your logistics operations, it is essential to plan the implementation carefully. This includes designing the robot paths, setting up charging stations, and integrating the robots with your warehouse management system.

Step 4: Train Your Staff

Training your staff on how to work with AGV robots is crucial for a successful implementation. Make sure your employees are familiar with the robots’ operation, safety protocols, and maintenance procedures.

Step 5: Monitor and Optimize

Once the AGV robots are deployed in your logistics operations, it is important to monitor their performance and optimize their operation continuously. Use data analytics to identify areas for improvement and make adjustments as needed.

Benefits of AGV Robot Solutions

- Increased Efficiency: AGV robots can handle material handling tasks faster and more accurately than manual labor.

- Cost Savings: By automating repetitive tasks, AGV robots can reduce labor costs and increase productivity.

- Improved Safety: AGV robots can work alongside human employees in a warehouse without posing a safety risk.

- Flexibility: AGV robots can be easily reprogrammed to adapt to changing logistics needs.

Overall, implementing AGV robot solutions for logistics can bring numerous benefits to your warehouse operations. By following the steps outlined in this article and carefully planning the implementation, you can streamline your material handling processes, increase efficiency, and stay ahead of the competition in the logistics industry.