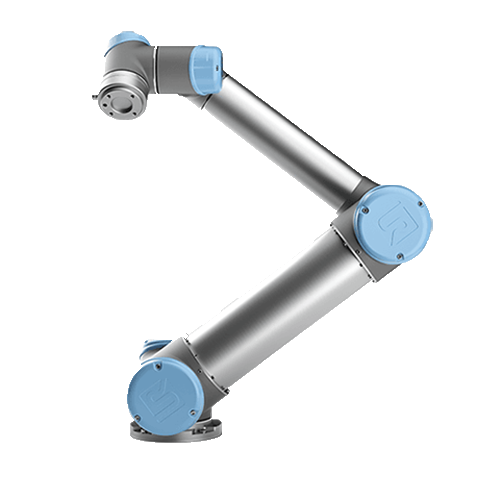

How to effectively use the UR5 robotic arm?

Welcome to the world of robotic automation! In this article, we will delve into the intricacies of using the UR5 robotic arm effectively in your operations. The UR5 robotic arm is a versatile and powerful tool that can revolutionize your production processes. By understanding its capabilities and implementing best practices, you can leverage its full potential to boost productivity and efficiency.

1. Familiarize yourself with the UR5 robotic arm

Before diving into using the UR5 robotic arm, it is essential to familiarize yourself with its components and functionalities. The UR5 robotic arm consists of six joints, allowing for a wide range of motion and flexibility. It is equipped with sensors and controllers that enable precise movements and interactions with the environment.

2. Programming the UR5 robotic arm

Programming the UR5 robotic arm is key to harnessing its capabilities. Whether you are a beginner or an experienced programmer, there are various methods to program the UR5 robotic arm, such as using teach pendant, offline programming software, or even coding in a programming language like Python.

3. Safety first

Prioritize safety when using the UR5 robotic arm. Implement safety protocols, such as restricting access to the robot’s work area, installing emergency stop buttons, and conducting regular maintenance checks. Remember, the safety of your operators is paramount.

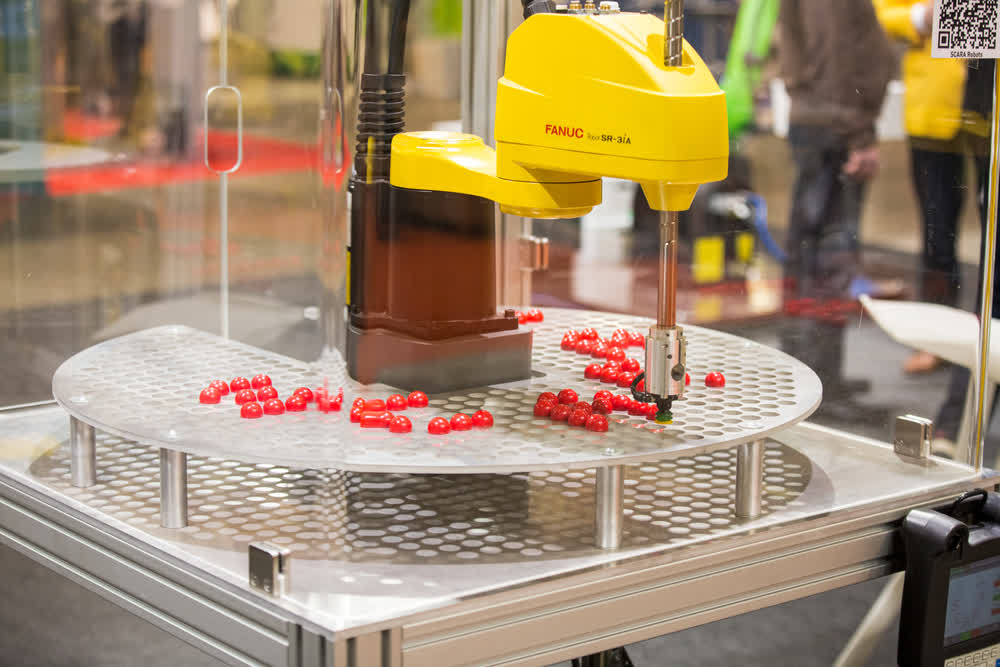

4. Optimize task planning

To maximize efficiency, carefully plan and optimize tasks that the UR5 robotic arm will perform. Analyze your production processes, identify repetitive tasks that can be automated, and create efficient workflows for the robot to follow. Consider factors like cycle time, tooling, and payload capacity when planning tasks.

5. Fine-tune robot parameters

To achieve optimal performance, regularly calibrate and fine-tune the UR5 robotic arm’s parameters. Adjust settings such as speed, acceleration, and precision to suit the specific requirements of your applications. Continuous optimization will ensure smooth operations and consistent results.

6. Monitoring and troubleshooting

Monitor the performance of the UR5 robotic arm and be vigilant for any signs of malfunction or deviation from expected behavior. Implement a robust maintenance schedule to keep the robot in top condition. In case of issues, promptly troubleshoot and resolve them to minimize downtime.

7. Training and skill development

Invest in training programs and skill development for your operators to enhance their proficiency in using the UR5 robotic arm. Provide hands-on training, simulation exercises, and resources for continuous learning. Empowered operators will maximize the potential of the robotic arm and contribute to your operations’ success.

8. Future-proofing with updates and upgrades

Stay informed about updates and upgrades available for the UR5 robotic arm to future-proof your operations. Regularly update software, firmware, and hardware components to access new features, enhancements, and improvements. By staying current with technology advancements, you can ensure that your robotic arm remains competitive and efficient.

Conclusion

In conclusion, effectively using the UR5 robotic arm requires a blend of technical knowledge, strategic planning, and ongoing optimization. By following best practices, prioritizing safety, and investing in training, you can unlock the full potential of the UR5 robotic arm and elevate your operations to new heights of productivity and efficiency. Embrace the future of automation with the UR5 robotic arm!

How to effectively use the UR5 robotic arm?

Welcome to the world of robotic automation! In this article, we will delve into the intricacies of using the UR5 robotic arm effectively in your operations. The UR5 robotic arm is a versatile and powerful tool that can revolutionize your production processes. By understanding its capabilities and implementing best practices, you can leverage its full potential to boost productivity and efficiency.

1. Familiarize yourself with the UR5 robotic arm

Before diving into using the UR5 robotic arm, it is essential to familiarize yourself with its components and functionalities. The UR5 robotic arm consists of six joints, allowing for a wide range of motion and flexibility. It is equipped with sensors and controllers that enable precise movements and interactions with the environment.

2. Programming the UR5 robotic arm

Programming the UR5 robotic arm is key to harnessing its capabilities. Whether you are a beginner or an experienced programmer, there are various methods to program the UR5 robotic arm, such as using teach pendant, offline programming software, or even coding in a programming language like Python.

3. Safety first

Prioritize safety when using the UR5 robotic arm. Implement safety protocols, such as restricting access to the robot’s work area, installing emergency stop buttons, and conducting regular maintenance checks. Remember, the safety of your operators is paramount.

4. Optimize task planning

To maximize efficiency, carefully plan and optimize tasks that the UR5 robotic arm will perform. Analyze your production processes, identify repetitive tasks that can be automated, and create efficient workflows for the robot to follow. Consider factors like cycle time, tooling, and payload capacity when planning tasks.

5. Fine-tune robot parameters

To achieve optimal performance, regularly calibrate and fine-tune the UR5 robotic arm’s parameters. Adjust settings such as speed, acceleration, and precision to suit the specific requirements of your applications. Continuous optimization will ensure smooth operations and consistent results.

6. Monitoring and troubleshooting

Monitor the performance of the UR5 robotic arm and be vigilant for any signs of malfunction or deviation from expected behavior. Implement a robust maintenance schedule to keep the robot in top condition. In case of issues, promptly troubleshoot and resolve them to minimize downtime.

7. Training and skill development

Invest in training programs and skill development for your operators to enhance their proficiency in using the UR5 robotic arm. Provide hands-on training, simulation exercises, and resources for continuous learning. Empowered operators will maximize the potential of the robotic arm and contribute to your operations’ success.

8. Future-proofing with updates and upgrades

Stay informed about updates and upgrades available for the UR5 robotic arm to future-proof your operations. Regularly update software, firmware, and hardware components to access new features, enhancements, and improvements. By staying current with technology advancements, you can ensure that your robotic arm remains competitive and efficient.

Conclusion

In conclusion, effectively using the UR5 robotic arm requires a blend of technical knowledge, strategic planning, and ongoing optimization. By following best practices, prioritizing safety, and investing in training, you can unlock the full potential of the UR5 robotic arm and elevate your operations to new heights of productivity and efficiency. Embrace the future of automation with the UR5 robotic arm!