How to choose the right inductor for a power supply?

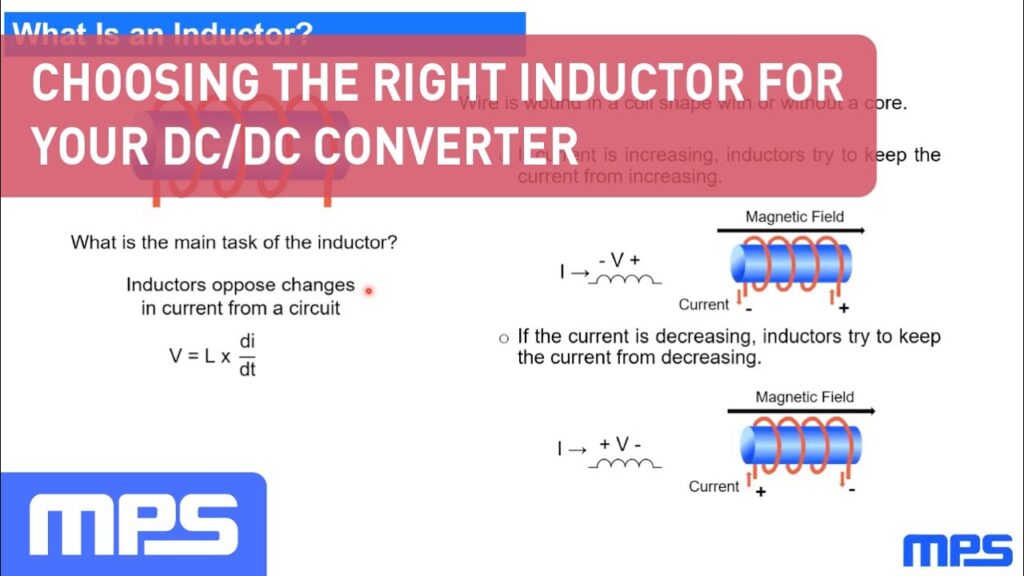

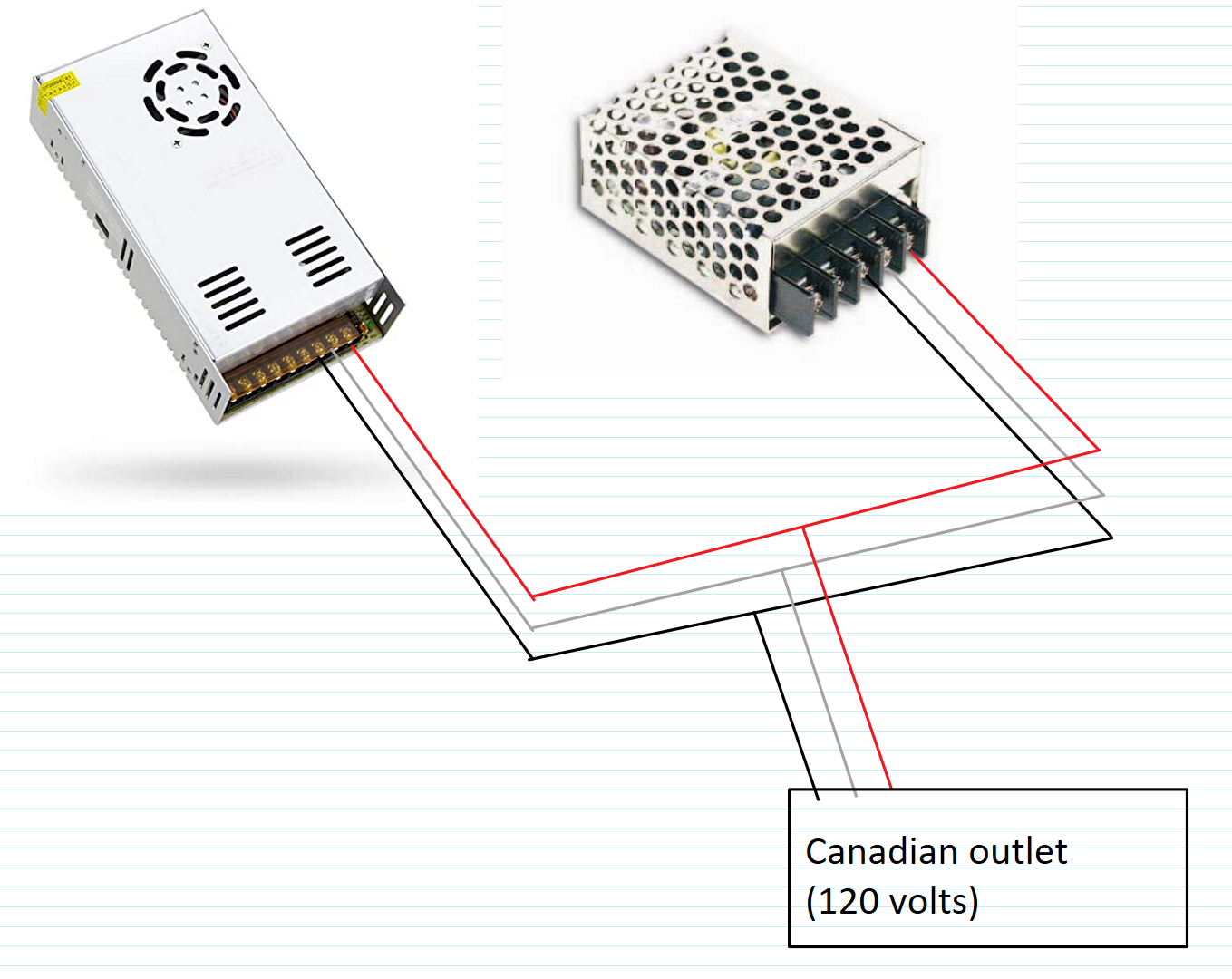

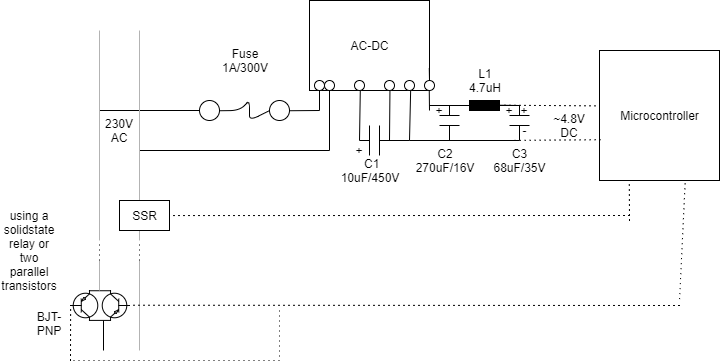

Choosing the right inductor for a power supply is crucial for optimal performance and efficiency. Inductors play a vital role in power supply circuits by storing and releasing energy as needed. In this article, we will discuss the key factors to consider when selecting an inductor for your power supply design.

1. Inductance Value

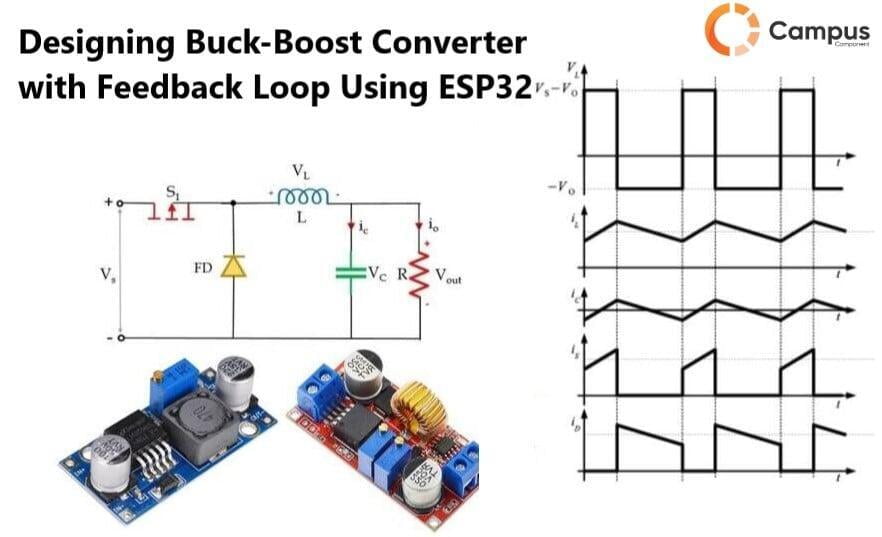

The most important factor to consider when selecting an inductor is the inductance value. Inductance is the ability of an inductor to store energy in the form of a magnetic field when current flows through it. The inductance value is typically measured in henries (H) or millihenries (mH). To determine the appropriate inductance value for your power supply, you need to consider the load current, frequency, and desired ripple voltage.

2. Saturation Current

Saturation current is another crucial parameter to consider when choosing an inductor for a power supply. Saturation current is the maximum current that an inductor can handle without experiencing a significant increase in core loss. It is essential to select an inductor with a saturation current rating higher than the peak current in your circuit to prevent saturation and ensure stable performance.

3. DC Resistance

DC resistance is the resistance of the wire winding in an inductor. Lower DC resistance results in reduced power loss and higher efficiency in a power supply circuit. When selecting an inductor, it is essential to consider the DC resistance value to minimize power dissipation and improve overall performance.

4. Size and Form Factor

The size and form factor of an inductor are important considerations, especially in space-constrained applications. The physical size and shape of an inductor can impact the overall layout and design of a power supply circuit. It is crucial to select an inductor that fits within the available space while meeting the performance requirements of the application.

5. Temperature Stability

Temperature stability is a critical factor to consider when choosing an inductor for a power supply. The performance of an inductor can vary with temperature changes, affecting the overall efficiency and reliability of the power supply circuit. It is essential to select an inductor with a high temperature stability rating to ensure consistent performance under varying operating conditions.

6. Manufacturer Reliability

Choosing an inductor from a reliable manufacturer is essential to ensure product quality and performance consistency. Reliable manufacturers follow strict quality control measures and provide detailed specifications for their products. It is advisable to select an inductor from a reputable manufacturer with a proven track record of delivering high-quality components.

7. Cost

Cost is also an important factor to consider when choosing an inductor for a power supply. While it is essential to prioritize performance and reliability, it is equally important to consider the cost implications of the selected inductor. It is advisable to strike a balance between cost and performance to ensure optimal value for your power supply design.

Conclusion

Choosing the right inductor for a power supply is a critical decision that can significantly impact the performance and efficiency of the circuit. By considering factors such as inductance value, saturation current, DC resistance, size and form factor, temperature stability, manufacturer reliability, and cost, you can select an inductor that meets the requirements of your power supply design. It is essential to conduct thorough research and consult with experienced engineers to make an informed decision and ensure the success of your power supply project.

How to choose the right inductor for a power supply?

Choosing the right inductor for a power supply is crucial for optimal performance and efficiency. Inductors play a vital role in power supply circuits by storing and releasing energy as needed. In this article, we will discuss the key factors to consider when selecting an inductor for your power supply design.

1. Inductance Value

The most important factor to consider when selecting an inductor is the inductance value. Inductance is the ability of an inductor to store energy in the form of a magnetic field when current flows through it. The inductance value is typically measured in henries (H) or millihenries (mH). To determine the appropriate inductance value for your power supply, you need to consider the load current, frequency, and desired ripple voltage.

2. Saturation Current

Saturation current is another crucial parameter to consider when choosing an inductor for a power supply. Saturation current is the maximum current that an inductor can handle without experiencing a significant increase in core loss. It is essential to select an inductor with a saturation current rating higher than the peak current in your circuit to prevent saturation and ensure stable performance.

3. DC Resistance

DC resistance is the resistance of the wire winding in an inductor. Lower DC resistance results in reduced power loss and higher efficiency in a power supply circuit. When selecting an inductor, it is essential to consider the DC resistance value to minimize power dissipation and improve overall performance.

4. Size and Form Factor

The size and form factor of an inductor are important considerations, especially in space-constrained applications. The physical size and shape of an inductor can impact the overall layout and design of a power supply circuit. It is crucial to select an inductor that fits within the available space while meeting the performance requirements of the application.

5. Temperature Stability

Temperature stability is a critical factor to consider when choosing an inductor for a power supply. The performance of an inductor can vary with temperature changes, affecting the overall efficiency and reliability of the power supply circuit. It is essential to select an inductor with a high temperature stability rating to ensure consistent performance under varying operating conditions.

6. Manufacturer Reliability

Choosing an inductor from a reliable manufacturer is essential to ensure product quality and performance consistency. Reliable manufacturers follow strict quality control measures and provide detailed specifications for their products. It is advisable to select an inductor from a reputable manufacturer with a proven track record of delivering high-quality components.

7. Cost

Cost is also an important factor to consider when choosing an inductor for a power supply. While it is essential to prioritize performance and reliability, it is equally important to consider the cost implications of the selected inductor. It is advisable to strike a balance between cost and performance to ensure optimal value for your power supply design.

Conclusion

Choosing the right inductor for a power supply is a critical decision that can significantly impact the performance and efficiency of the circuit. By considering factors such as inductance value, saturation current, DC resistance, size and form factor, temperature stability, manufacturer reliability, and cost, you can select an inductor that meets the requirements of your power supply design. It is essential to conduct thorough research and consult with experienced engineers to make an informed decision and ensure the success of your power supply project.