How to Check a Transformer Winding

Transformers play a crucial role in the functioning of many electrical systems. To ensure that a transformer is operating efficiently, it is important to regularly check its windings. Transformer windings are a critical component of the transformer, and any damage or fault in them can lead to serious issues. In this article, we will discuss how to check transformer windings to ensure the smooth operation of the transformer.

1. Visual Inspection

The first step in checking transformer windings is to visually inspect them. Look for any signs of damage such as burn marks, discoloration, or physical deformities. Inspect the insulation material around the windings to ensure it is intact and not damaged. A visual inspection can help identify any obvious issues with the windings.

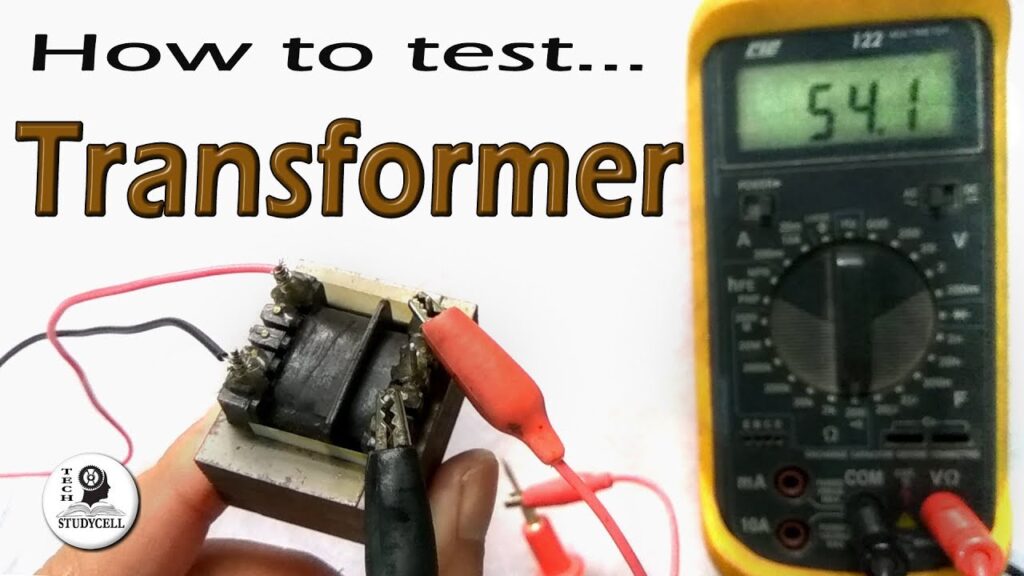

2. Resistance Testing

One of the most common methods to check transformer windings is through resistance testing. To perform this test, disconnect the transformer from the power source and measure the resistance of the windings using a multimeter. Compare the measured resistance with the manufacturer’s specifications to determine if the windings are within acceptable limits.

3. Insulation Resistance Testing

Insulation resistance testing is another important test to check the condition of transformer windings. This test is done to check the insulation resistance between the windings and the core of the transformer. A low insulation resistance value indicates a fault in the insulation material, which can lead to short circuits and other issues.

4. Polarity Testing

Checking the polarity of the transformer windings is crucial to ensure they are connected correctly. Incorrect polarity can lead to inefficiencies and damage to the transformer. Use a multimeter to check the polarity of each winding and correct any issues if needed.

5. Turns Ratio Testing

Turns ratio testing is performed to check the turns ratio of the transformer windings. This test helps ensure that the windings are functioning as designed and the transformer is operating efficiently. Use a turns ratio meter to perform this test and compare the measured ratio with the manufacturer’s specifications.

6. Frequency Response Analysis

Frequency response analysis is a more advanced method to check transformer windings. This test involves applying a range of frequencies to the windings and analyzing the response to identify any faults or abnormalities. Frequency response analysis can help detect issues that may not be visible through other testing methods.

7. Temperature Rise Testing

Temperature rise testing is conducted to check the temperature rise of the transformer windings under load. Excessive temperature rise can indicate issues with the windings, such as overloading or poor insulation. Monitor the temperature rise of the windings during operation to ensure they are within safe limits.

Conclusion

Regularly checking transformer windings is essential to ensure the reliable operation of the transformer and prevent potential issues. By following the above methods for checking transformer windings, you can identify any faults or abnormalities early on and take corrective actions to maintain the transformer’s efficiency and longevity.

How to Check a Transformer Winding

Transformers play a crucial role in the functioning of many electrical systems. To ensure that a transformer is operating efficiently, it is important to regularly check its windings. Transformer windings are a critical component of the transformer, and any damage or fault in them can lead to serious issues. In this article, we will discuss how to check transformer windings to ensure the smooth operation of the transformer.

1. Visual Inspection

The first step in checking transformer windings is to visually inspect them. Look for any signs of damage such as burn marks, discoloration, or physical deformities. Inspect the insulation material around the windings to ensure it is intact and not damaged. A visual inspection can help identify any obvious issues with the windings.

2. Resistance Testing

One of the most common methods to check transformer windings is through resistance testing. To perform this test, disconnect the transformer from the power source and measure the resistance of the windings using a multimeter. Compare the measured resistance with the manufacturer’s specifications to determine if the windings are within acceptable limits.

3. Insulation Resistance Testing

Insulation resistance testing is another important test to check the condition of transformer windings. This test is done to check the insulation resistance between the windings and the core of the transformer. A low insulation resistance value indicates a fault in the insulation material, which can lead to short circuits and other issues.

4. Polarity Testing

Checking the polarity of the transformer windings is crucial to ensure they are connected correctly. Incorrect polarity can lead to inefficiencies and damage to the transformer. Use a multimeter to check the polarity of each winding and correct any issues if needed.

5. Turns Ratio Testing

Turns ratio testing is performed to check the turns ratio of the transformer windings. This test helps ensure that the windings are functioning as designed and the transformer is operating efficiently. Use a turns ratio meter to perform this test and compare the measured ratio with the manufacturer’s specifications.

6. Frequency Response Analysis

Frequency response analysis is a more advanced method to check transformer windings. This test involves applying a range of frequencies to the windings and analyzing the response to identify any faults or abnormalities. Frequency response analysis can help detect issues that may not be visible through other testing methods.

7. Temperature Rise Testing

Temperature rise testing is conducted to check the temperature rise of the transformer windings under load. Excessive temperature rise can indicate issues with the windings, such as overloading or poor insulation. Monitor the temperature rise of the windings during operation to ensure they are within safe limits.

Conclusion

Regularly checking transformer windings is essential to ensure the reliable operation of the transformer and prevent potential issues. By following the above methods for checking transformer windings, you can identify any faults or abnormalities early on and take corrective actions to maintain the transformer’s efficiency and longevity.