Best Way to Detect Liquid Levels with a Float Switch

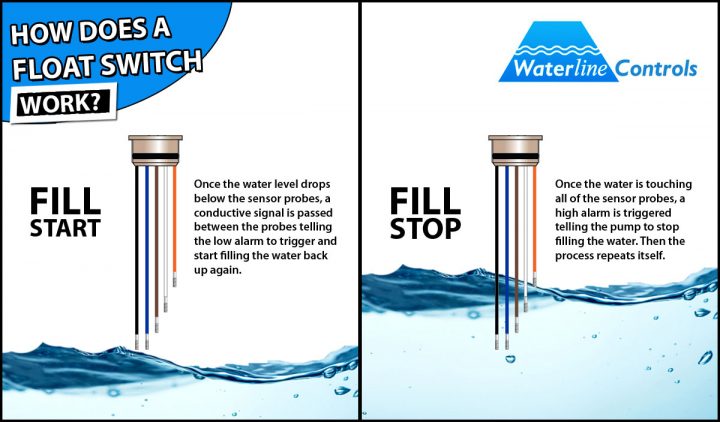

When it comes to monitoring liquid levels in tanks or other containers, using a float switch is one of the most effective and reliable methods available. Float switches are simple devices that can detect the level of a liquid by floating on the surface and triggering a switch when the liquid reaches a certain point. They are commonly used in applications such as sump pumps, water tanks, and oil tanks.

But what is the best way to detect liquid levels with a float switch? In this article, we will explore some tips and tricks for maximizing the effectiveness of your float switch system.

Choose the Right Type of Float Switch

When it comes to selecting a float switch for your application, it is important to choose the right type for the job. There are several different types of float switches available, including vertical float switches, horizontal float switches, and tethered float switches. Each type has its own advantages and disadvantages, so it is important to consider the specific requirements of your application when making your selection.

For example, vertical float switches are ideal for applications where space is limited, while horizontal float switches are better suited for wide, open tanks. Tethered float switches are often used in applications where the liquid level can vary significantly, such as in a sump pump.

Proper Installation is Key

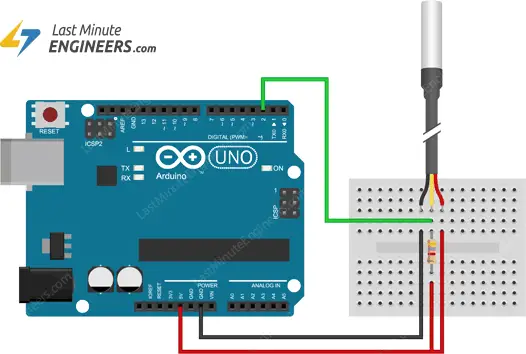

One of the most important factors in ensuring the effectiveness of your float switch system is proper installation. It is essential to position the float switch at the correct level in the tank to ensure accurate readings. Additionally, the float switch should be securely mounted to prevent it from moving around or becoming damaged.

When installing a float switch, be sure to follow the manufacturer’s guidelines and recommendations. This will help to ensure that your float switch functions properly and provides accurate readings of the liquid level.

Regular Maintenance is Essential

Like any other mechanical device, float switches require regular maintenance to ensure optimal performance. It is important to inspect the float switch periodically to check for any signs of wear or damage. Additionally, the float switch should be cleaned regularly to prevent the build-up of debris or contaminants that could affect its operation.

By performing regular maintenance on your float switch system, you can help to prevent costly repairs and downtime. It is also a good idea to keep a record of your maintenance activities to track the performance of your float switch over time.

Consider External Factors

When designing a float switch system, it is important to consider any external factors that could affect its performance. For example, changes in temperature or pressure can cause the liquid level to fluctuate, which could impact the accuracy of the float switch readings.

To minimize the impact of external factors on your float switch system, consider installing additional sensors or controls that can help to compensate for these variations. It is also a good idea to regularly calibrate your float switch to ensure that it is providing accurate readings.

Conclusion

Float switches are an effective and reliable method for detecting liquid levels in tanks and other containers. By choosing the right type of float switch, ensuring proper installation, performing regular maintenance, and considering external factors, you can maximize the effectiveness of your float switch system.

Remember to consult with a professional if you have any questions or concerns about your float switch system. With the right approach, you can ensure that your float switch provides accurate and reliable readings of liquid levels for years to come.

Best Way to Detect Liquid Levels with a Float Switch

When it comes to monitoring liquid levels in tanks or other containers, using a float switch is one of the most effective and reliable methods available. Float switches are simple devices that can detect the level of a liquid by floating on the surface and triggering a switch when the liquid reaches a certain point. They are commonly used in applications such as sump pumps, water tanks, and oil tanks.

But what is the best way to detect liquid levels with a float switch? In this article, we will explore some tips and tricks for maximizing the effectiveness of your float switch system.

Choose the Right Type of Float Switch

When it comes to selecting a float switch for your application, it is important to choose the right type for the job. There are several different types of float switches available, including vertical float switches, horizontal float switches, and tethered float switches. Each type has its own advantages and disadvantages, so it is important to consider the specific requirements of your application when making your selection.

For example, vertical float switches are ideal for applications where space is limited, while horizontal float switches are better suited for wide, open tanks. Tethered float switches are often used in applications where the liquid level can vary significantly, such as in a sump pump.

Proper Installation is Key

One of the most important factors in ensuring the effectiveness of your float switch system is proper installation. It is essential to position the float switch at the correct level in the tank to ensure accurate readings. Additionally, the float switch should be securely mounted to prevent it from moving around or becoming damaged.

When installing a float switch, be sure to follow the manufacturer’s guidelines and recommendations. This will help to ensure that your float switch functions properly and provides accurate readings of the liquid level.

Regular Maintenance is Essential

Like any other mechanical device, float switches require regular maintenance to ensure optimal performance. It is important to inspect the float switch periodically to check for any signs of wear or damage. Additionally, the float switch should be cleaned regularly to prevent the build-up of debris or contaminants that could affect its operation.

By performing regular maintenance on your float switch system, you can help to prevent costly repairs and downtime. It is also a good idea to keep a record of your maintenance activities to track the performance of your float switch over time.

Consider External Factors

When designing a float switch system, it is important to consider any external factors that could affect its performance. For example, changes in temperature or pressure can cause the liquid level to fluctuate, which could impact the accuracy of the float switch readings.

To minimize the impact of external factors on your float switch system, consider installing additional sensors or controls that can help to compensate for these variations. It is also a good idea to regularly calibrate your float switch to ensure that it is providing accurate readings.

Conclusion

Float switches are an effective and reliable method for detecting liquid levels in tanks and other containers. By choosing the right type of float switch, ensuring proper installation, performing regular maintenance, and considering external factors, you can maximize the effectiveness of your float switch system.

Remember to consult with a professional if you have any questions or concerns about your float switch system. With the right approach, you can ensure that your float switch provides accurate and reliable readings of liquid levels for years to come.