How to Set Up a RAD Robot for Industrial Applications

Robots have become an integral part of modern industrial processes, offering automation, efficiency, and precision. Among the various types of robots, RAD (Robotics for Automated Device) robots are particularly popular for industrial applications due to their versatility and ease of programming. If you are looking to set up a RAD robot for your industrial operations, this guide will walk you through the essential steps to ensure a smooth and successful installation.

Step 1: Define Your Requirements

Before you begin the setup process, it is crucial to define your specific requirements and goals for using the RAD robot in your industrial applications. Consider factors such as the tasks the robot will perform, the working environment, the production volume, and any other relevant parameters that will impact the robot’s performance.

Step 2: Choose the Right RAD Robot Model

Once you have a clear understanding of your requirements, research and select the appropriate RAD robot model that best suits your needs. Consider factors such as payload capacity, reach, accuracy, and speed to ensure that the robot can effectively perform the desired tasks in your industrial setting.

Step 3: Install the RAD Robot Hardware

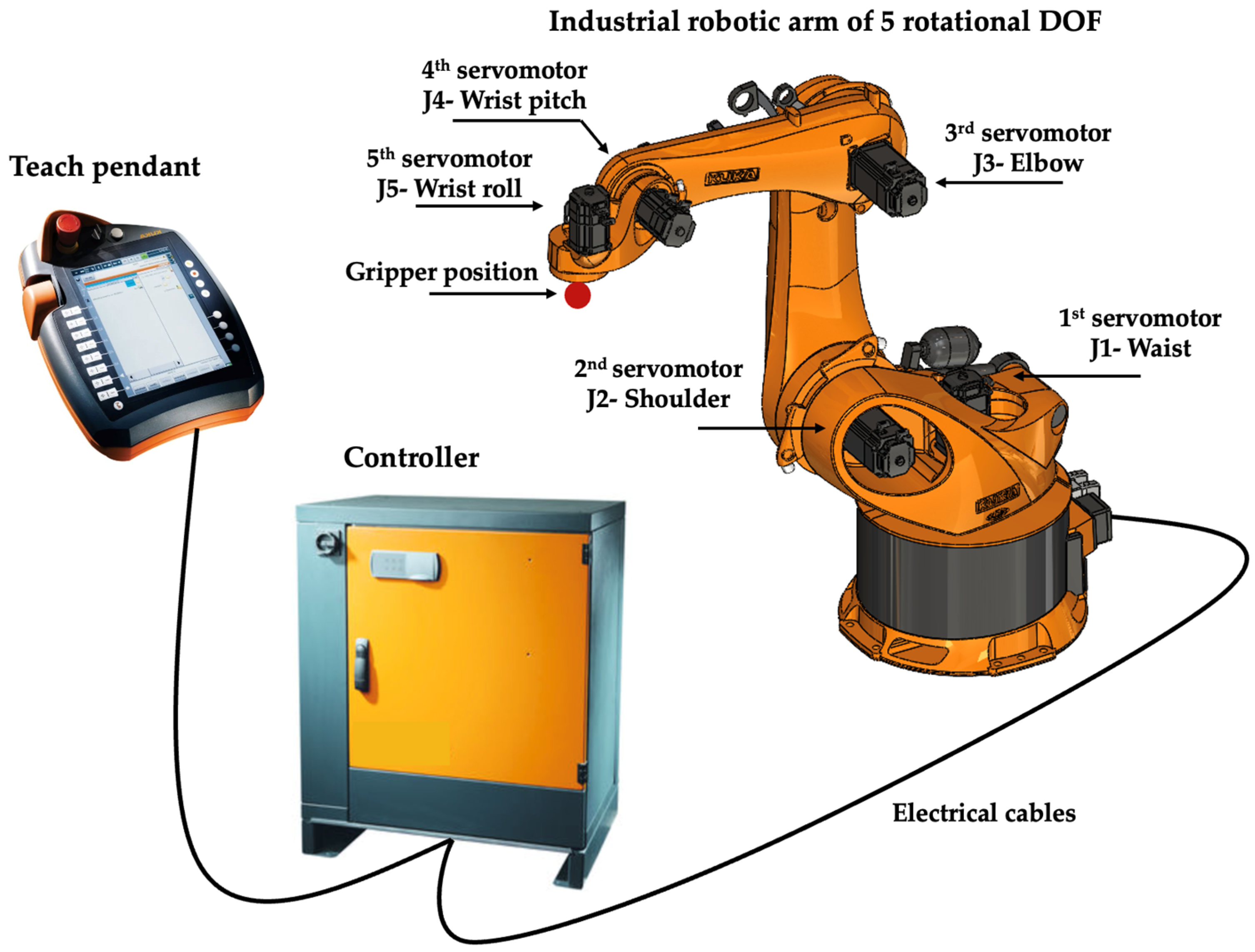

Begin the setup process by installing the hardware components of the RAD robot. This may include mounting the robot arm, attaching end-effectors, connecting cables, and ensuring that the robot is securely positioned in its designated workspace. Follow the manufacturer’s instructions carefully to ensure proper installation and alignment of the robot components.

Step 4: Program the RAD Robot

After installing the hardware, the next step is to program the RAD robot to perform the required tasks. Depending on the complexity of the tasks, you may need to use programming languages such as C++, Python, or dedicated software provided by the robot manufacturer. Ensure that the robot’s movements are accurate, efficient, and safe for operation in the industrial environment.

Step 5: Test and Calibrate the RAD Robot

Once the robot is programmed, conduct thorough testing to ensure that it performs the tasks correctly and meets the required specifications. Calibrate the robot’s sensors, actuators, and controllers to optimize its performance and ensure smooth operation in the industrial setting. Make any necessary adjustments to fine-tune the robot’s movements and responsiveness.

Step 6: Implement Safety Protocols

Ensure that the RAD robot is equipped with appropriate safety features and protocols to prevent accidents and injuries in the industrial environment. Implement safety barriers, emergency stop buttons, and other safety measures to protect human operators and other equipment from potential hazards associated with robot operation.

Step 7: Monitor and Maintain the RAD Robot

Regularly monitor the RAD robot’s performance and conduct routine maintenance to ensure optimal functionality and longevity. Keep track of any signs of wear and tear, software updates, and performance issues that may arise over time. Address any maintenance or repair needs promptly to prevent costly downtime and disruptions to your industrial operations.

Conclusion

Setting up a RAD robot for industrial applications requires careful planning, thorough preparation, and systematic execution of the installation process. By following the steps outlined in this guide, you can ensure a successful setup and integration of the RAD robot into your industrial workflow, enhancing efficiency, productivity, and safety in your operations.

Was this helpful?

0 / 0