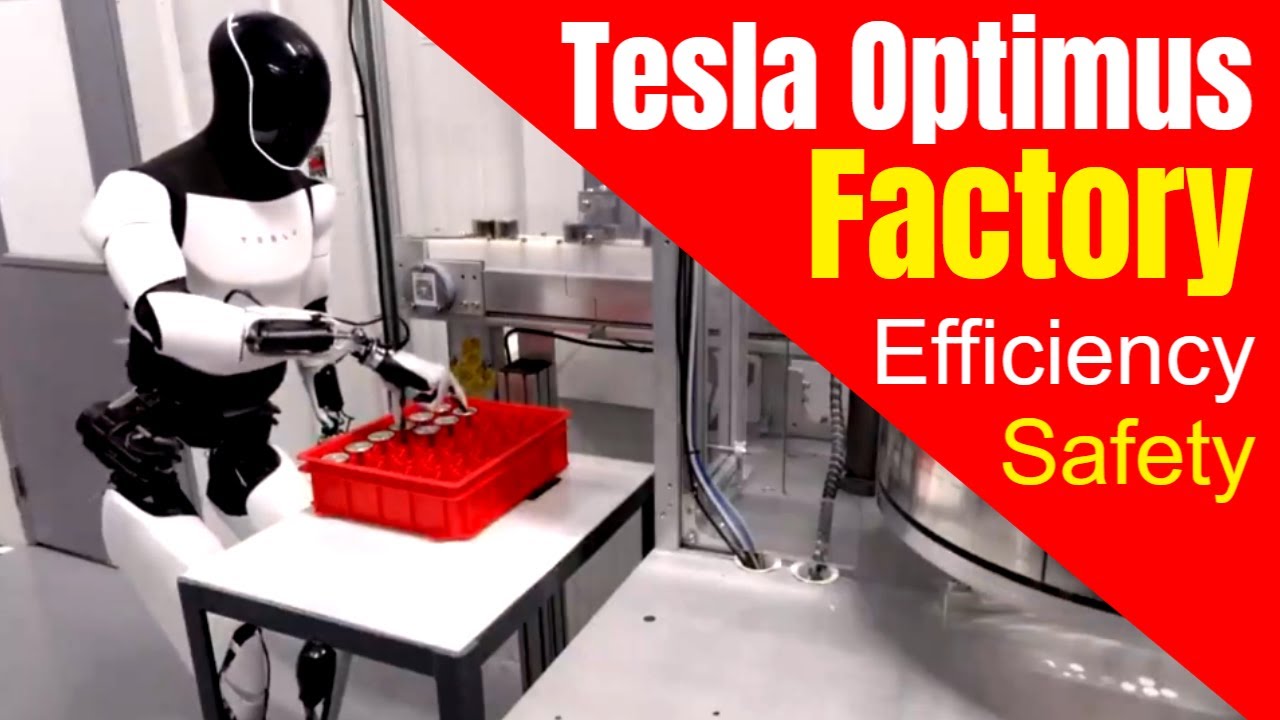

How to Configure an Optimus Robot for Industrial Use?

Robots have become an integral part of modern industrial processes, streamlining operations and increasing efficiency. Optimus robots, in particular, are known for their advanced capabilities and versatility in industrial settings. In this article, we will explore the steps involved in configuring an Optimus robot for industrial use to ensure optimal performance and productivity.

Step 1: Understand Your Requirements

Before you begin configuring your Optimus robot, it is essential to understand your specific requirements and goals. Assess your manufacturing process, identify the tasks that the robot will be performing, and determine the desired outcomes. This will help you tailor the configuration to suit your specific needs and maximize the robot’s effectiveness.

Step 2: Select the Right Robot Model

Optimus offers a range of robot models with varying capabilities and specifications. Choose a robot model that aligns with your requirements and can perform the necessary tasks efficiently. Consider factors such as payload capacity, reach, and speed when selecting the right robot for your industrial application.

Step 3: Install and Set Up the Robot

Once you have selected the appropriate robot model, it is time to install and set up the robot in your industrial facility. Follow the manufacturer’s instructions carefully to ensure proper installation and configuration. Configure the robot’s settings, including motion parameters, tooling, and safety features, to optimize its performance in your specific application.

Step 4: Program the Robot

Programming is a crucial step in configuring an Optimus robot for industrial use. Develop a detailed programming sequence that defines the robot’s tasks, movements, and interactions with other equipment. Test the program thoroughly to ensure that the robot performs as expected and makes any necessary adjustments to optimize its performance.

Step 5: Integrate the Robot into Your Production Line

Integrating the robot seamlessly into your production line is essential to maximize its efficiency and productivity. Ensure that the robot is synchronized with other equipment and processes to avoid bottlenecks and optimize workflow. Conduct thorough testing and validation to confirm that the robot operates smoothly within your production environment.

Step 6: Monitor and Maintain the Robot

Regular monitoring and maintenance are necessary to keep your Optimus robot in top condition and prevent unexpected downtime. Implement a maintenance schedule to inspect the robot’s components, perform necessary repairs or replacements, and update software as needed. Continuous monitoring will help identify any issues early and ensure uninterrupted operation.

Conclusion

Configuring an Optimus robot for industrial use requires careful planning, technical expertise, and regular maintenance. By following the steps outlined in this article, you can optimize your robot’s performance, streamline your manufacturing processes, and achieve greater efficiency in your industrial operations. With the right configuration and integration, an Optimus robot can revolutionize your production line and drive success in your industrial endeavors.

Was this helpful?

0 / 0