How to program a robot arm for automation tasks?

Robot arms are an essential component of automation in various industries, ranging from manufacturing to healthcare. Programming a robot arm effectively is crucial to ensuring smooth and efficient operation. In this article, we will explore the steps involved in programming a robot arm for automation tasks.

Step 1: Understand the Robot Arm

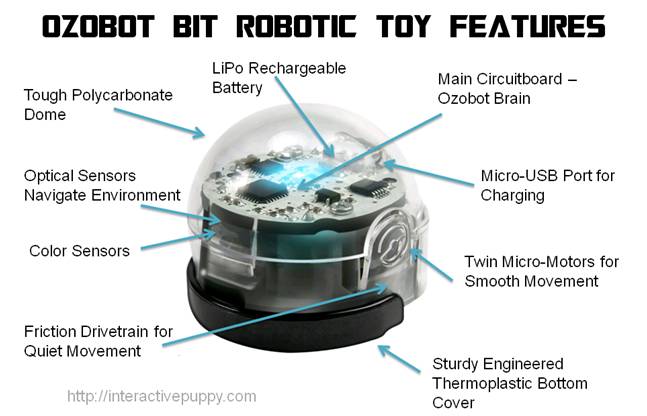

Before you start programming the robot arm, it is essential to have a clear understanding of its capabilities and limitations. Familiarize yourself with the different axes of motion, payload capacity, reach, and end-effector options. This knowledge will help you tailor your programming to optimize the robot arm’s performance.

Step 2: Choose the Right Programming Language

There are various programming languages used in robot arm programming, such as C++, Python, and ROS (Robot Operating System). Choose a language that best suits your application and your team’s expertise. Ensure that the programming language supports the robot arm’s controller and communication protocols.

Step 3: Develop a Motion Plan

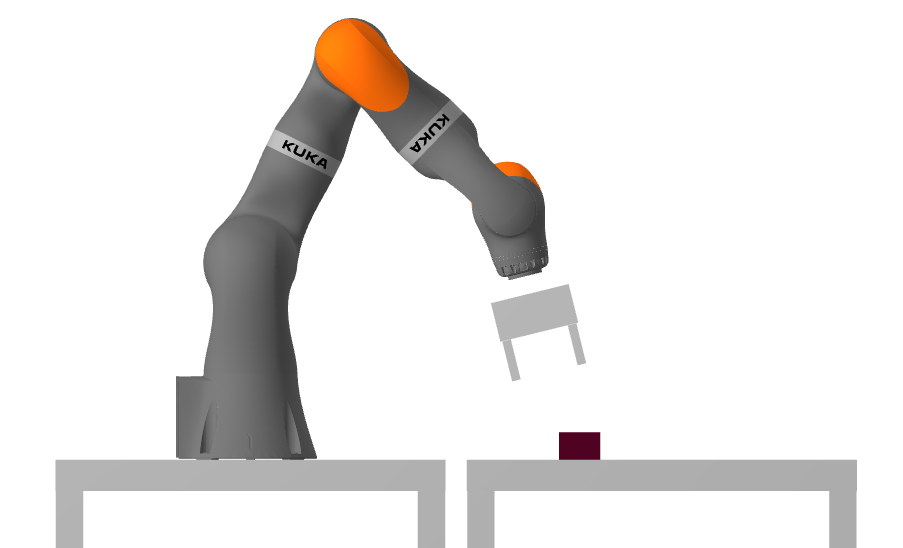

Before writing the actual code, it is crucial to develop a motion plan for the robot arm. Define the sequence of movements, positions, and orientations required to complete the automation task. Consider factors such as path planning, collision avoidance, and trajectory optimization to ensure smooth and precise movements.

Step 4: Write the Code

Once you have a clear motion plan, it’s time to write the code for the robot arm. Break down the task into smaller sub-tasks, such as pick-and-place, assembly, or welding, and write code snippets for each sub-task. Test the code on a simulation environment before deploying it on the actual robot arm.

Step 5: Debug and Optimize

After writing the code, debug and optimize it to improve the robot arm’s performance. Test the code under different scenarios and conditions to identify and fix any potential issues. Optimize the code for speed, accuracy, and efficiency to maximize the robot arm’s productivity.

Step 6: Integrate with Other Systems

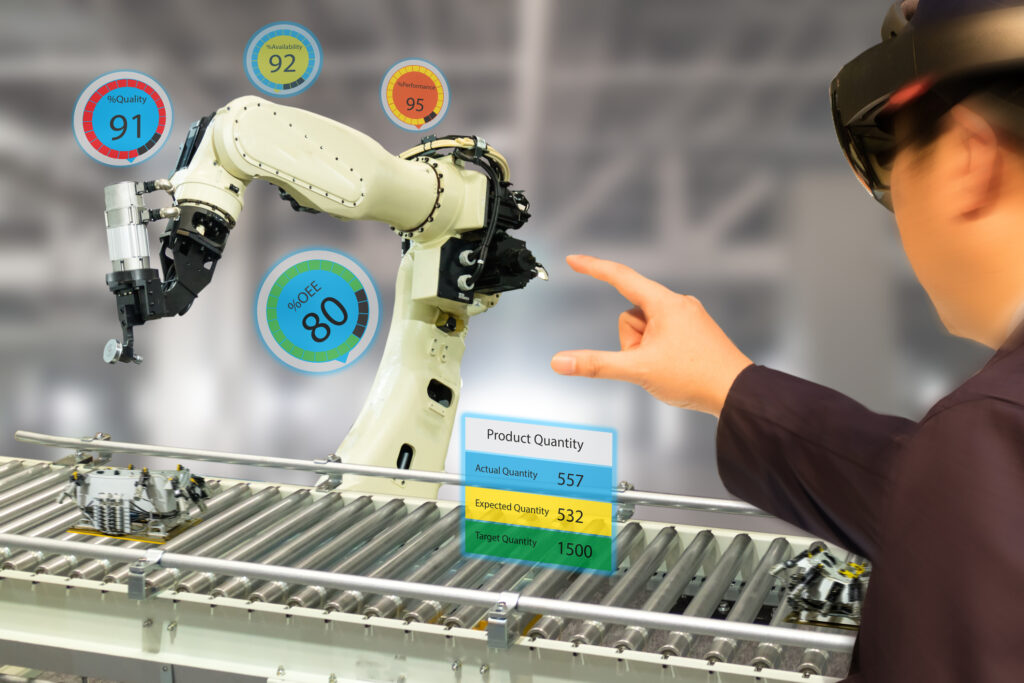

Once the robot arm programming is complete, integrate it with other systems, such as sensors, cameras, and PLCs (Programmable Logic Controllers). Ensure seamless communication and synchronization between the robot arm and peripheral devices to achieve a fully automated workflow.

Step 7: Continuous Monitoring and Maintenance

Lastly, continuously monitor the robot arm’s performance and conduct regular maintenance to ensure smooth operation. Keep track of key performance metrics, such as cycle time, accuracy, and downtime, and address any issues promptly. Regular maintenance will prolong the robot arm’s lifespan and prevent costly breakdowns.

Conclusion

Programming a robot arm for automation tasks requires a systematic approach and attention to detail. By understanding the robot arm, choosing the right programming language, developing a motion plan, writing efficient code, debugging and optimizing, integrating with other systems, and conducting continuous monitoring and maintenance, you can program a robot arm effectively to enhance productivity and efficiency in your operations.

How to program a robot arm for automation tasks?

Robot arms are an essential component of automation in various industries, ranging from manufacturing to healthcare. Programming a robot arm effectively is crucial to ensuring smooth and efficient operation. In this article, we will explore the steps involved in programming a robot arm for automation tasks.

Step 1: Understand the Robot Arm

Before you start programming the robot arm, it is essential to have a clear understanding of its capabilities and limitations. Familiarize yourself with the different axes of motion, payload capacity, reach, and end-effector options. This knowledge will help you tailor your programming to optimize the robot arm’s performance.

Step 2: Choose the Right Programming Language

There are various programming languages used in robot arm programming, such as C++, Python, and ROS (Robot Operating System). Choose a language that best suits your application and your team’s expertise. Ensure that the programming language supports the robot arm’s controller and communication protocols.

Step 3: Develop a Motion Plan

Before writing the actual code, it is crucial to develop a motion plan for the robot arm. Define the sequence of movements, positions, and orientations required to complete the automation task. Consider factors such as path planning, collision avoidance, and trajectory optimization to ensure smooth and precise movements.

Step 4: Write the Code

Once you have a clear motion plan, it’s time to write the code for the robot arm. Break down the task into smaller sub-tasks, such as pick-and-place, assembly, or welding, and write code snippets for each sub-task. Test the code on a simulation environment before deploying it on the actual robot arm.

Step 5: Debug and Optimize

After writing the code, debug and optimize it to improve the robot arm’s performance. Test the code under different scenarios and conditions to identify and fix any potential issues. Optimize the code for speed, accuracy, and efficiency to maximize the robot arm’s productivity.

Step 6: Integrate with Other Systems

Once the robot arm programming is complete, integrate it with other systems, such as sensors, cameras, and PLCs (Programmable Logic Controllers). Ensure seamless communication and synchronization between the robot arm and peripheral devices to achieve a fully automated workflow.

Step 7: Continuous Monitoring and Maintenance

Lastly, continuously monitor the robot arm’s performance and conduct regular maintenance to ensure smooth operation. Keep track of key performance metrics, such as cycle time, accuracy, and downtime, and address any issues promptly. Regular maintenance will prolong the robot arm’s lifespan and prevent costly breakdowns.

Conclusion

Programming a robot arm for automation tasks requires a systematic approach and attention to detail. By understanding the robot arm, choosing the right programming language, developing a motion plan, writing efficient code, debugging and optimizing, integrating with other systems, and conducting continuous monitoring and maintenance, you can program a robot arm effectively to enhance productivity and efficiency in your operations.