How to explore cobotics for collaborative automation?

In recent years, collaborative robots, or cobots, have become an increasingly popular option for businesses looking to automate their processes. Unlike traditional industrial robots, cobots are designed to work alongside humans, enhancing productivity and efficiency in the workplace. In this article, we will explore how you can leverage cobotics for collaborative automation in your business.

1. Understand the benefits of cobotics

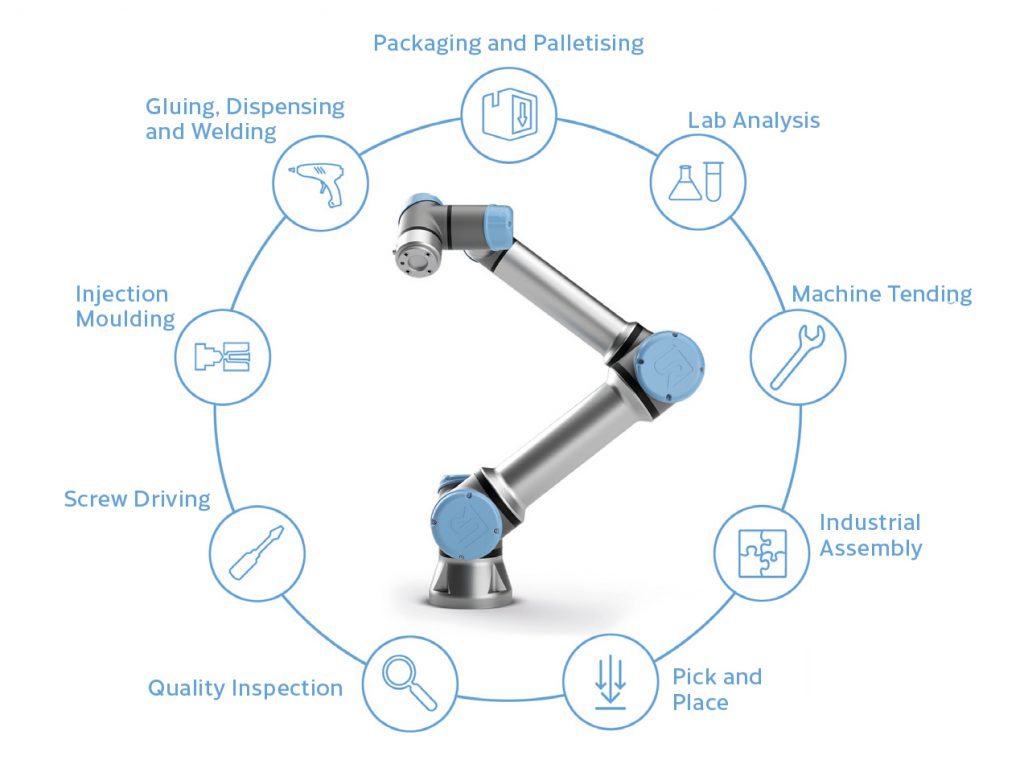

Before diving into the world of cobots, it’s essential to understand the numerous benefits they can bring to your business. Cobots are known for their flexibility, ease of use, and cost-effectiveness. They can be easily programmed to perform a wide range of tasks, from simple pick-and-place operations to more complex assembly tasks. By integrating cobots into your automation process, you can improve efficiency, increase production output, and enhance workplace safety.

2. Assess your automation needs

Once you’ve familiarized yourself with the benefits of cobotics, it’s time to assess your automation needs. Identify areas in your production process where cobots can be effectively utilized. Consider tasks that are repetitive, time-consuming, or pose a safety risk to human workers. By pinpointing these areas, you can determine the best way to integrate cobots into your workflow.

3. Choose the right cobot for your business

Not all cobots are created equal, so it’s crucial to choose the right one for your business. Consider factors such as payload capacity, reach, and speed when selecting a cobot model. Additionally, think about the safety features and programming capabilities that are essential for your specific needs. By choosing the right cobot, you can maximize its potential in your automation process.

4. Train your employees on cobotics

Integrating cobots into your workplace requires training your employees on how to work alongside these machines. Provide comprehensive training on cobot programming, maintenance, and safety protocols to ensure that your employees can effectively collaborate with cobots. By investing in employee training, you can promote a smooth transition to cobotics in your workplace.

5. Implement cobotics into your automation process

Once you’ve selected the right cobot and trained your employees, it’s time to implement cobotics into your automation process. Start by integrating cobots into pilot projects or small-scale tasks to evaluate their performance and efficiency. As you gain confidence in cobotics, gradually expand their role in your production process. Monitor their performance and make any necessary adjustments to optimize their function within your workflow.

6. Evaluate the impact of cobotics on your business

After implementing cobotics into your automation process, take the time to evaluate their impact on your business. Measure key performance indicators such as production output, efficiency gains, and cost savings to determine the effectiveness of cobotics. Solicit feedback from your employees on their experience working with cobots and identify areas for improvement. By evaluating the impact of cobotics, you can make data-driven decisions to further enhance your automation process.

Was this helpful?

0 / 0