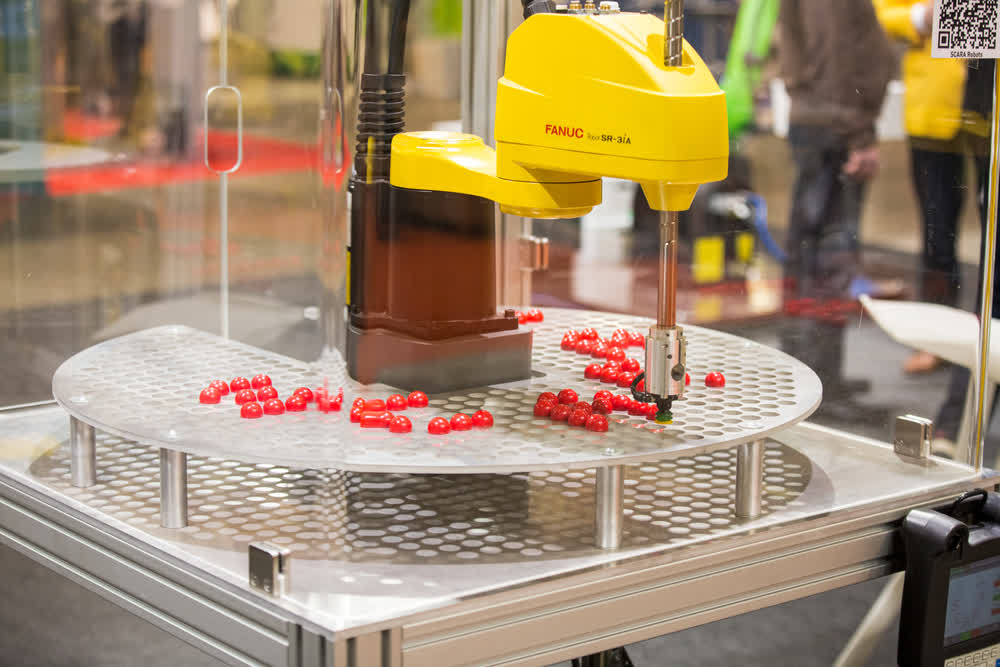

How to configure a SCARA robot for high‑precision tasks?

SCARA (Selective Compliance Assembly Robot Arm) robots are ideal for high-precision tasks in various industries, including electronics, pharmaceuticals, and more. These robots are known for their speed, accuracy, and flexibility, making them a popular choice for manufacturers looking to increase productivity and efficiency.

Key steps to configure a SCARA robot for high-precision tasks:

- 1. Understand the task requirements: Before configuring the SCARA robot, it is essential to understand the specific requirements of the task it will be performing. This includes the precision needed, the speed of operation, the range of motion required, and any other specific parameters.

- 2. Choose the right end-effector: The end-effector is the tool attached to the robot that interacts with the workpiece. Selecting the right end-effector is crucial for achieving high precision in tasks. Consider factors such as grip strength, flexibility, and accuracy when choosing an end-effector.

- 3. Optimize the robot’s trajectory: Programming the robot’s trajectory is essential for achieving high precision in tasks. Ensure that the robot moves smoothly and accurately to avoid any errors or defects in the final product. Use motion planning software to optimize the trajectory for the task at hand.

- 4. Fine-tune the robot’s parameters: SCARA robots come with various parameters that can be adjusted to optimize performance. These include speed, acceleration, deceleration, and more. Fine-tuning these parameters based on the task requirements can significantly improve the robot’s precision and efficiency.

- 5. Implement feedback systems: Feedback systems such as encoders and sensors can provide real-time data on the robot’s position, speed, and accuracy. Implementing feedback systems can help the robot make precise adjustments during operation, ensuring high precision in tasks.

- 6. Conduct regular maintenance: To ensure optimal performance, it is essential to conduct regular maintenance on the SCARA robot. This includes checking for wear and tear, replacing worn-out parts, and calibrating the robot’s sensors. Regular maintenance can prolong the robot’s lifespan and maintain its high precision over time.

By following these key steps and techniques, you can effectively configure a SCARA robot for high-precision tasks. With the right tools, software, and maintenance practices in place, your SCARA robot can deliver consistent and reliable performance, helping you achieve high-quality results in your manufacturing processes.

Was this helpful?

0 / 0