How to implement robot automation in industrial processes?

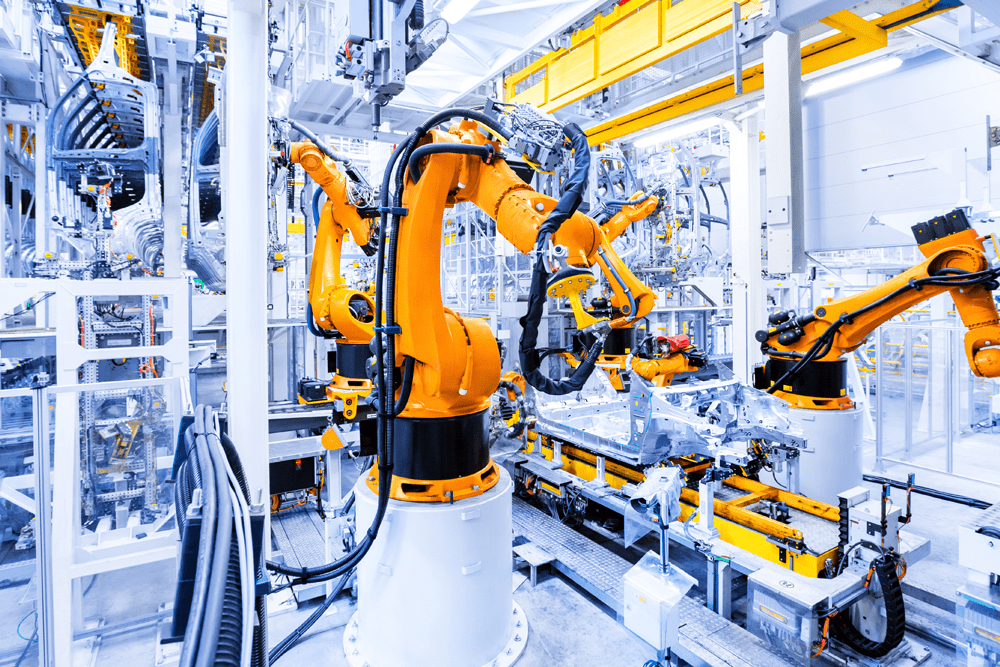

In today’s rapidly changing industrial landscape, the implementation of robot automation has become increasingly crucial for companies looking to streamline their processes, increase efficiency, and stay competitive. Robots can perform repetitive tasks with precision and speed, freeing up human workers to focus on more complex, high-value tasks. However, implementing robot automation in industrial processes is not without its challenges. In this article, we will explore the key steps to successfully implement robot automation in industrial processes.

Step 1: Conduct a thorough assessment of your current processes

- Identify the tasks that are most suitable for robot automation

- Evaluate the current workflow and identify potential bottlenecks or inefficiencies that robots can help address

- Assess the skill level and training requirements for operating and maintaining robots

By conducting a thorough assessment of your current processes, you can determine the areas where robot automation can have the most significant impact and develop a clear implementation strategy.

Step 2: Choose the right robotic system

- Consider the size and weight of the objects that the robot will handle

- Evaluate the required reach and payload capacity of the robot

- Choose a robot with the necessary flexibility and adaptability to handle a variety of tasks

It is essential to select a robotic system that is well-suited to the specific needs of your industrial processes to ensure successful implementation and maximize the benefits of automation.

Step 3: Design a comprehensive implementation plan

- Develop a timeline for the implementation of robot automation

- Identify key performance indicators to measure the success of the implementation

- Allocate resources and personnel for training and deployment

Creating a detailed implementation plan will help ensure that the transition to robot automation is smooth and that the desired outcomes are achieved.

Step 4: Provide training and support for employees

- Offer training programs to familiarize employees with the operation and maintenance of robots

- Provide ongoing support and guidance to help employees adapt to the changes brought about by automation

Ensuring that employees are properly trained and supported throughout the implementation process is essential for the successful integration of robot automation into industrial processes.

Step 5: Monitor and evaluate the implementation

- Track key performance indicators to measure the impact of robot automation on productivity and efficiency

- Collect feedback from employees and stakeholders to identify areas for improvement

By continuously monitoring and evaluating the implementation of robot automation, you can make necessary adjustments and improvements to optimize the benefits of automation for your industrial processes.

In conclusion, implementing robot automation in industrial processes can bring significant benefits in terms of efficiency, productivity, and competitiveness. By following the key steps outlined in this article and carefully planning and executing the implementation process, companies can successfully integrate robot automation into their operations and position themselves for future growth and success.

Was this helpful?

0 / 0