Best way to calibrate a load cell for accuracy

Calibrating a load cell is crucial for ensuring accurate readings and optimal performance. A load cell is a transducer that converts force into an electrical signal. Proper calibration is essential to maintain accuracy and precision in measuring weight or force. In this article, we’ll explore the best way to calibrate a load cell to achieve accurate results.

Understanding Load Cell Calibration

Calibration is the process of adjusting a load cell to accurately measure the applied force. This involves comparing the output of the load cell with a known standard to determine any deviations or errors. Calibration ensures that the load cell provides consistent and reliable measurements over time.

There are two main methods for calibrating a load cell:

- Dead-weight calibration

- Using a calibration system

Dead-Weight Calibration

Dead-weight calibration is a manual method that involves applying known weights to the load cell and comparing the output readings. This method is straightforward but requires precision weights and careful handling to ensure accurate results. Dead-weight calibration is suitable for calibrating small to medium-sized load cells.

Here’s how you can calibrate a load cell using the dead-weight method:

- Verify the load cell specifications and ensure it is in good condition.

- Apply a known weight to the load cell and record the output readings.

- Adjust the load cell’s sensitivity or output to match the known weight.

- Repeat the process with different weights to create a calibration curve.

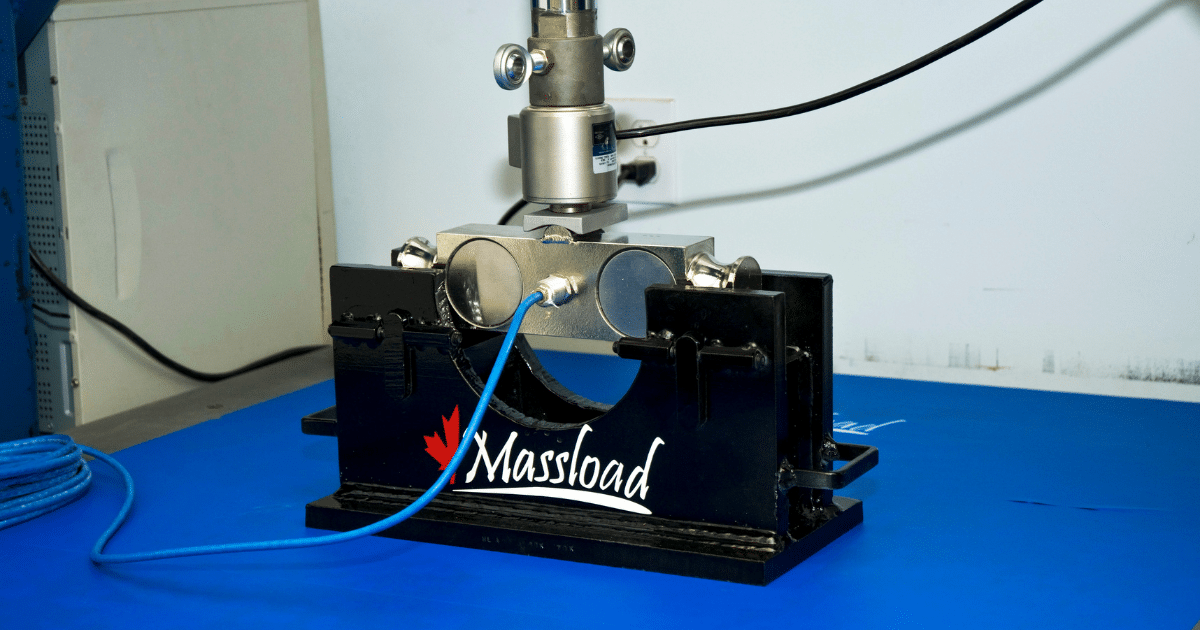

Using a Calibration System

Using a calibration system involves a more automated process using specialized equipment to apply and measure forces on the load cell. This method is suitable for calibrating larger load cells or high-precision applications where accuracy is critical. A calibration system typically includes load frames, force sensors, and software for data analysis.

To calibrate a load cell using a calibration system, follow these steps:

- Set up the load cell and calibration system according to the manufacturer’s instructions.

- Apply a range of known forces to the load cell and record the output readings.

- Compare the readings to the expected values and make adjustments as needed.

- Create a calibration report documenting the results and adjustments made.

Best Practices for Load Cell Calibration

Regardless of the calibration method used, there are some best practices to ensure accurate and reliable results:

- Calibrate the load cell regularly to account for environmental factors and wear.

- Handle the load cell with care to prevent damage or deformation.

- Use proper equipment and weights for calibration to ensure accuracy.

- Document the calibration process and results for traceability and quality control.

By following these best practices and choosing the appropriate calibration method, you can ensure that your load cell delivers accurate and reliable measurements for your weighing or force measurement needs.

Calibrating a load cell is essential for maintaining accuracy and reliability in your measurements. Whether you choose the dead-weight method or a calibration system, proper calibration ensures that your load cell delivers consistent and precise results over time.

Was this helpful?

0 / 0