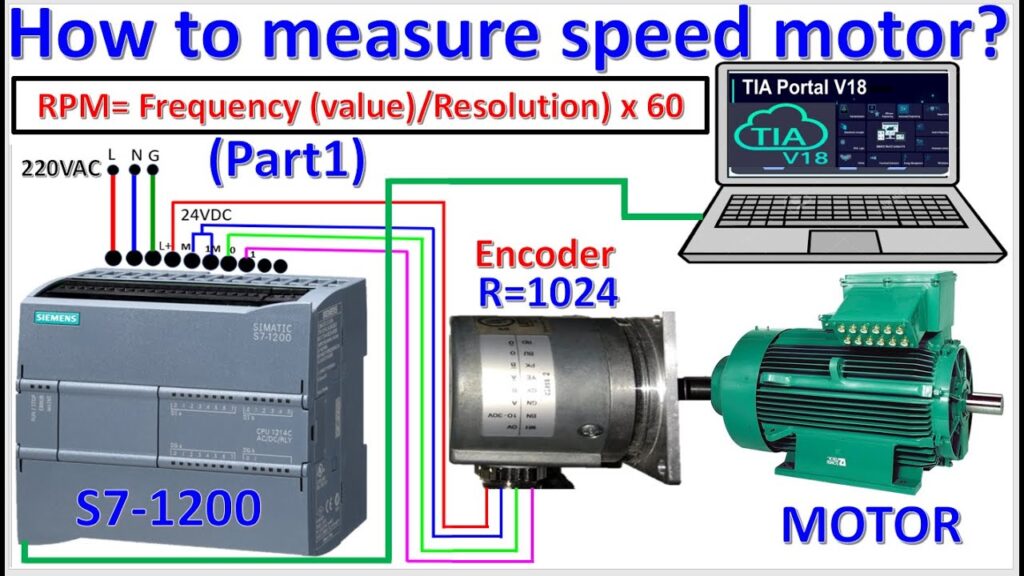

How to Measure the Speed of a Motor with an Encoder

Measuring the speed of a motor is crucial in many industrial applications where precise control is needed. One common way to measure the speed of a motor is by using an encoder. An encoder is a device that converts the angular position or motion of a shaft into an analog or digital signal. In this article, we will discuss how to measure the speed of a motor using an encoder and the steps involved in the process.

What is an Encoder?

An encoder is a sensor that translates the position or motion of a rotating shaft into an electrical signal. There are two main types of encoders: incremental encoders and absolute encoders. Incremental encoders provide information about the relative position of the shaft, while absolute encoders provide information about the exact position of the shaft. Encoders are commonly used in motors to provide feedback on speed, position, and direction.

How Does an Encoder Work?

Encoders work by generating pulses as the shaft rotates. The number of pulses generated per revolution is known as the resolution of the encoder. By counting these pulses over a specific period of time, the speed of the motor can be calculated. The more pulses per revolution, the higher the resolution and accuracy of the speed measurement. Encoders are connected to the motor shaft and send signals to a controller or a computer for processing.

Steps to Measure Motor Speed with an Encoder

- Choose the appropriate encoder: Select an encoder with the right resolution and accuracy for your motor application.

- Install the encoder: Attach the encoder to the motor shaft following the manufacturer’s instructions.

- Connect the encoder: Wire the encoder to the motor controller or a computer using the specified connections.

- Calibrate the encoder: Configure the encoder settings on the controller or computer to ensure accurate speed measurements.

- Count pulses: Monitor the number of pulses generated by the encoder over a set period of time to calculate the motor speed.

- Calculate speed: Use the formula speed = (pulses per revolution * 60) / time period to determine the motor speed in revolutions per minute (RPM).

Benefits of Using an Encoder to Measure Motor Speed

Using an encoder to measure motor speed offers several advantages, including:

- High accuracy: Encoders provide precise speed measurements due to their high resolution and digital output.

- Real-time feedback: Encoders offer instant feedback on motor speed, allowing for quick adjustments and control.

- Adaptability: Encoders can be easily integrated into different motor systems and applications for versatile speed monitoring.

- Reliability: Encoders are durable and reliable devices that can withstand harsh industrial environments.

Conclusion

Measuring the speed of a motor with an encoder is a practical and efficient way to ensure precise control and performance. By following the steps outlined in this article, you can accurately measure the speed of your motor and optimize its operation. Using an encoder provides real-time feedback, high accuracy, and reliability, making it an ideal solution for various industrial applications.

How to Measure the Speed of a Motor with an Encoder

Measuring the speed of a motor is crucial in many industrial applications where precise control is needed. One common way to measure the speed of a motor is by using an encoder. An encoder is a device that converts the angular position or motion of a shaft into an analog or digital signal. In this article, we will discuss how to measure the speed of a motor using an encoder and the steps involved in the process.

What is an Encoder?

An encoder is a sensor that translates the position or motion of a rotating shaft into an electrical signal. There are two main types of encoders: incremental encoders and absolute encoders. Incremental encoders provide information about the relative position of the shaft, while absolute encoders provide information about the exact position of the shaft. Encoders are commonly used in motors to provide feedback on speed, position, and direction.

How Does an Encoder Work?

Encoders work by generating pulses as the shaft rotates. The number of pulses generated per revolution is known as the resolution of the encoder. By counting these pulses over a specific period of time, the speed of the motor can be calculated. The more pulses per revolution, the higher the resolution and accuracy of the speed measurement. Encoders are connected to the motor shaft and send signals to a controller or a computer for processing.

Steps to Measure Motor Speed with an Encoder

- Choose the appropriate encoder: Select an encoder with the right resolution and accuracy for your motor application.

- Install the encoder: Attach the encoder to the motor shaft following the manufacturer’s instructions.

- Connect the encoder: Wire the encoder to the motor controller or a computer using the specified connections.

- Calibrate the encoder: Configure the encoder settings on the controller or computer to ensure accurate speed measurements.

- Count pulses: Monitor the number of pulses generated by the encoder over a set period of time to calculate the motor speed.

- Calculate speed: Use the formula speed = (pulses per revolution * 60) / time period to determine the motor speed in revolutions per minute (RPM).

Benefits of Using an Encoder to Measure Motor Speed

Using an encoder to measure motor speed offers several advantages, including:

- High accuracy: Encoders provide precise speed measurements due to their high resolution and digital output.

- Real-time feedback: Encoders offer instant feedback on motor speed, allowing for quick adjustments and control.

- Adaptability: Encoders can be easily integrated into different motor systems and applications for versatile speed monitoring.

- Reliability: Encoders are durable and reliable devices that can withstand harsh industrial environments.

Conclusion

Measuring the speed of a motor with an encoder is a practical and efficient way to ensure precise control and performance. By following the steps outlined in this article, you can accurately measure the speed of your motor and optimize its operation. Using an encoder provides real-time feedback, high accuracy, and reliability, making it an ideal solution for various industrial applications.