Best Way to Measure Vibration Using a Piezoelectric Sensor

Vibration measurement is crucial in various industries such as automotive, aerospace, and manufacturing. It helps in monitoring the health of machines, detecting faults, and ensuring smooth operations. One of the most commonly used sensors for measuring vibration is the piezoelectric sensor. In this article, we will discuss the best way to measure vibration using a piezoelectric sensor.

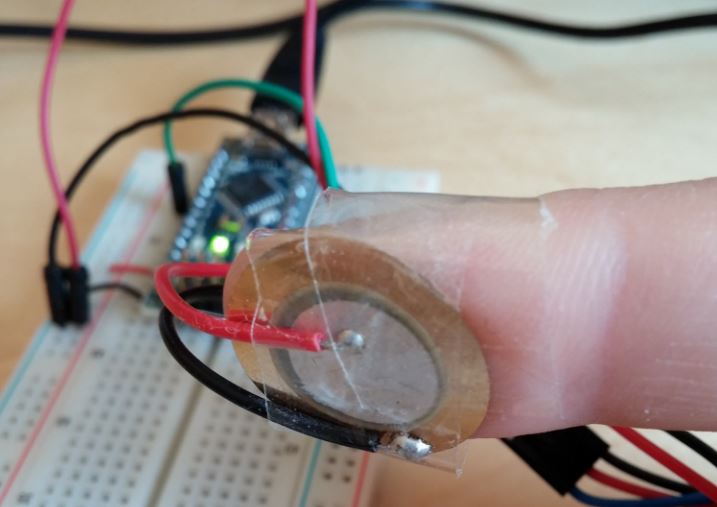

What is a Piezoelectric Sensor?

A piezoelectric sensor is a type of sensor that measures changes in pressure, acceleration, temperature, or force and converts them into an electrical charge. It is composed of piezoelectric materials that generate an electric charge proportional to the mechanical stress applied to them. Piezoelectric sensors are commonly used in various applications such as vibration monitoring, impact sensing, and pressure sensing.

How Does a Piezoelectric Sensor Measure Vibration?

When a piezoelectric sensor is subjected to vibration, it generates an electrical charge proportional to the vibration amplitude. This electrical charge is then converted into a voltage signal by the sensor’s electronics. The voltage signal can be further processed and analyzed to determine the characteristics of the vibration, such as frequency, amplitude, and duration.

Best Practices for Measuring Vibration Using a Piezoelectric Sensor

When measuring vibration using a piezoelectric sensor, it is important to follow best practices to ensure accurate and reliable results. Here are some tips to help you get the best measurements:

- Calibrate the sensor: Before using the piezoelectric sensor for vibration measurement, it is important to calibrate it to ensure accurate readings. Follow the manufacturer’s instructions for calibration and make sure to use proper calibration equipment.

- Mount the sensor properly: The way the piezoelectric sensor is mounted can significantly impact the measurement results. Make sure to mount the sensor securely and in the correct orientation to minimize errors.

- Use appropriate signal conditioning: To obtain accurate vibration measurements, it is essential to use proper signal conditioning equipment. This includes amplifiers, filters, and data acquisition systems.

- Consider environmental factors: Vibration measurements can be influenced by environmental factors such as temperature, humidity, and electromagnetic interference. Take these factors into account when setting up the measurement system.

- Analyze data thoroughly: Once you have collected vibration data using the piezoelectric sensor, make sure to analyze it thoroughly to draw meaningful conclusions. Use advanced signal processing techniques to extract valuable information from the data.

Applications of Vibration Measurement with Piezoelectric Sensors

Piezoelectric sensors are widely used for vibration measurement in various industries and applications. Some common applications include:

- Structural health monitoring in buildings and bridges

- Machine condition monitoring in manufacturing plants

- Vibration testing in automotive and aerospace industries

- Seismic monitoring and earthquake detection

By following the best practices and using piezoelectric sensors effectively, you can ensure accurate and reliable vibration measurements for your specific application.

Overall, piezoelectric sensors are an excellent choice for vibration measurement due to their high sensitivity, fast response time, and wide frequency range. By following the best practices outlined in this article, you can make the most of your piezoelectric sensor and obtain accurate vibration measurements for your application.

Was this helpful?

0 / 0