How to Use a Force-Sensitive Resistor (FSR) Sensor

A force-sensitive resistor (FSR) sensor is a type of pressure sensor that changes its resistance based on the force or pressure applied to it. These sensors are widely used in various applications such as touch screens, medical devices, and robotics. In this article, we will discuss how to use an FSR sensor to detect force or pressure.

1. Understanding FSR Sensor

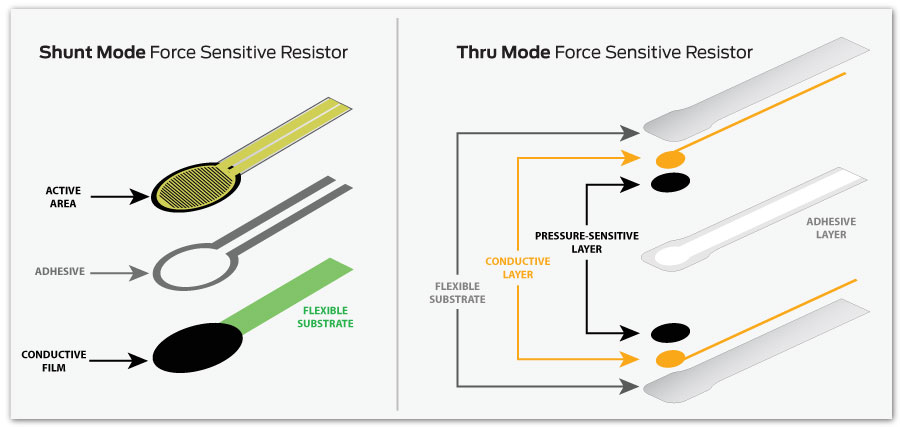

Before using an FSR sensor, it is essential to understand how it works. An FSR sensor consists of a conductive polymer material that changes its resistance when pressure is applied. The resistance decreases as the force applied to the sensor increases. This change in resistance can be measured using an analog-to-digital converter (ADC) to determine the force or pressure applied.

2. Connecting the FSR Sensor

To use an FSR sensor, you need to connect it to a microcontroller or Arduino board. The sensor has two leads, one for power (VCC) and the other for ground (GND). Connect the power lead to the 5V output of the microcontroller or board and the ground lead to the ground pin. The signal lead of the sensor should be connected to an analog input pin of the microcontroller to read the resistance value.

3. Reading the Sensor Data

Once the FSR sensor is connected, you can start reading the sensor data. Use the analogRead() function in Arduino programming to read the analog value from the sensor. This value represents the resistance of the sensor, which can be used to calculate the force or pressure applied. You can also use a calibration factor to map the resistance values to force or pressure units.

4. Interpreting the Sensor Data

After reading the sensor data, you can interpret it to determine the force or pressure applied. The resistance value can be converted to force using a known calibration curve or formula. You can also create thresholds to detect specific force levels and trigger actions accordingly. The sensor data can be displayed on a screen or used to control other devices based on the force detected.

5. Calibration and Testing

It is essential to calibrate the FSR sensor to ensure accurate force detection. Calibration involves mapping the resistance values to force or pressure units using known weights or pressures. Test the sensor with different force levels to verify its accuracy and adjust the calibration as needed. You can also test the sensor’s response time and sensitivity to fine-tune its performance.

6. Applications of FSR Sensor

FSR sensors are used in a wide range of applications, including robotics, medical devices, gaming controllers, and musical instruments. These sensors can be used to detect touch, pressure, or force in various scenarios. By using an FSR sensor, you can add interactive and responsive features to your projects and create innovative solutions that rely on force or pressure detection.

Conclusion

Using a force-sensitive resistor (FSR) sensor can add a new dimension to your projects by enabling force or pressure detection. By understanding how FSR sensors work, connecting them to a microcontroller, reading the sensor data, interpreting the results, calibrating and testing the sensor, and exploring its applications, you can leverage the power of FSR sensors in various projects. Experiment with FSR sensors to create interactive and responsive applications that respond to touch, pressure, or force inputs.

Was this helpful?

0 / 0