How to program a Cartesian robot for precise movements?

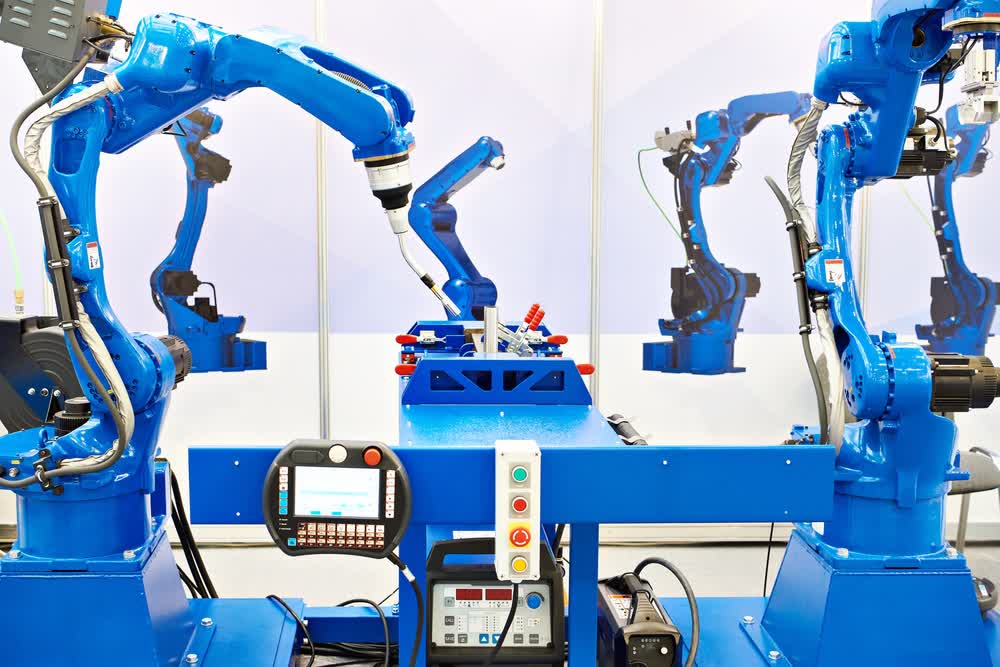

Cartesian robots play a crucial role in industrial automation, performing intricate tasks with precision and accuracy. Programming these robots for precise movements is essential to ensure efficiency and productivity in manufacturing processes. In this guide, we will explore the steps involved in programming a Cartesian robot for precise movements.

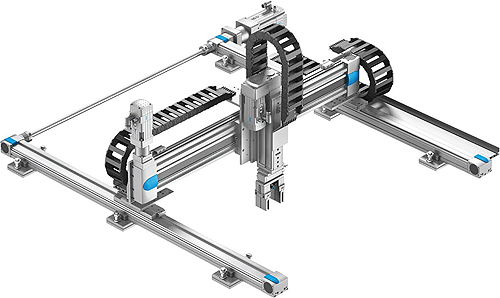

Understanding Cartesian Robots

Cartesian robots, also known as gantry robots or linear robots, are robotic systems that utilize Cartesian coordinates (X, Y, Z) to perform tasks in a three-dimensional space. These robots consist of linear axes that move along predetermined paths to manipulate objects or tools with precision.

- Cartesian robots are commonly used in applications such as pick-and-place operations, material handling, welding, and packaging.

- These robots are known for their high repeatability and accuracy, making them ideal for tasks that require precise movements.

Programming a Cartesian Robot

Programming a Cartesian robot involves defining the movement paths and sequences that the robot will follow to perform a specific task. This process requires a combination of hardware configuration, software programming, and testing to ensure the robot’s movements are precise and error-free.

Steps to program a Cartesian robot for precise movements:

- Configure the robot’s hardware: Set up the Cartesian robot’s mechanical components, including the linear axes, motors, and end effectors. Calibrate the robot to ensure accurate movement along the X, Y, and Z axes.

- Install the programming software: Use software tools such as Robot Operating System (ROS) or proprietary programming languages to create programs for the Cartesian robot. These programs will define the robot’s movement paths, speed, and acceleration profiles.

- Create movement paths: Define the Cartesian coordinates for the robot’s movement paths using the programming software. Specify the start and end points, as well as any intermediate waypoints the robot should follow.

- Set motion parameters: Configure the speed, acceleration, and deceleration of the robot’s movement along each axis to ensure smooth and precise motions. Fine-tune these parameters to optimize the robot’s performance based on the task requirements.

- Test the program: Verify the program’s functionality by running simulations or test movements with the Cartesian robot. Make adjustments to the program as needed to correct any errors or optimize the robot’s movements.

- Implement safety measures: Ensure that the Cartesian robot is equipped with safety features such as emergency stop buttons, protective barriers, and sensors to prevent accidents during operation. Conduct regular maintenance and safety checks to keep the robot in optimal condition.

By following these steps and best practices, you can effectively program a Cartesian robot for precise movements in industrial automation applications. With proper programming and calibration, Cartesian robots can enhance productivity, quality, and efficiency in manufacturing processes.

How to program a Cartesian robot for precise movements?

Cartesian robots play a crucial role in industrial automation, performing intricate tasks with precision and accuracy. Programming these robots for precise movements is essential to ensure efficiency and productivity in manufacturing processes. In this guide, we will explore the steps involved in programming a Cartesian robot for precise movements.

Understanding Cartesian Robots

Cartesian robots, also known as gantry robots or linear robots, are robotic systems that utilize Cartesian coordinates (X, Y, Z) to perform tasks in a three-dimensional space. These robots consist of linear axes that move along predetermined paths to manipulate objects or tools with precision.

- Cartesian robots are commonly used in applications such as pick-and-place operations, material handling, welding, and packaging.

- These robots are known for their high repeatability and accuracy, making them ideal for tasks that require precise movements.

Programming a Cartesian Robot

Programming a Cartesian robot involves defining the movement paths and sequences that the robot will follow to perform a specific task. This process requires a combination of hardware configuration, software programming, and testing to ensure the robot’s movements are precise and error-free.

Steps to program a Cartesian robot for precise movements:

- Configure the robot’s hardware: Set up the Cartesian robot’s mechanical components, including the linear axes, motors, and end effectors. Calibrate the robot to ensure accurate movement along the X, Y, and Z axes.

- Install the programming software: Use software tools such as Robot Operating System (ROS) or proprietary programming languages to create programs for the Cartesian robot. These programs will define the robot’s movement paths, speed, and acceleration profiles.

- Create movement paths: Define the Cartesian coordinates for the robot’s movement paths using the programming software. Specify the start and end points, as well as any intermediate waypoints the robot should follow.

- Set motion parameters: Configure the speed, acceleration, and deceleration of the robot’s movement along each axis to ensure smooth and precise motions. Fine-tune these parameters to optimize the robot’s performance based on the task requirements.

- Test the program: Verify the program’s functionality by running simulations or test movements with the Cartesian robot. Make adjustments to the program as needed to correct any errors or optimize the robot’s movements.

- Implement safety measures: Ensure that the Cartesian robot is equipped with safety features such as emergency stop buttons, protective barriers, and sensors to prevent accidents during operation. Conduct regular maintenance and safety checks to keep the robot in optimal condition.

By following these steps and best practices, you can effectively program a Cartesian robot for precise movements in industrial automation applications. With proper programming and calibration, Cartesian robots can enhance productivity, quality, and efficiency in manufacturing processes.