How to Design a 48V Battery Pack

Designing a 48V battery pack can be a complex but rewarding process. Whether you are a hobbyist building an electric bike or a professional designing a backup power system, getting the design right is crucial for optimal performance and safety. In this article, we will guide you through the key steps and considerations when designing a 48V battery pack.

1. Determine Your Power Requirements

The first step in designing a 48V battery pack is to determine your power requirements. This involves calculating the total power consumption of your system and the runtime needed. By knowing the power demands, you can size your battery pack accordingly to ensure it can deliver the required power over the desired duration.

2. Choose the Right Battery Chemistry

There are various battery chemistries available for 48V battery packs, each with its pros and cons. Some common options include lithium-ion, lead-acid, and nickel-metal hydride. Consider factors such as energy density, cycle life, and cost when selecting the right chemistry for your application.

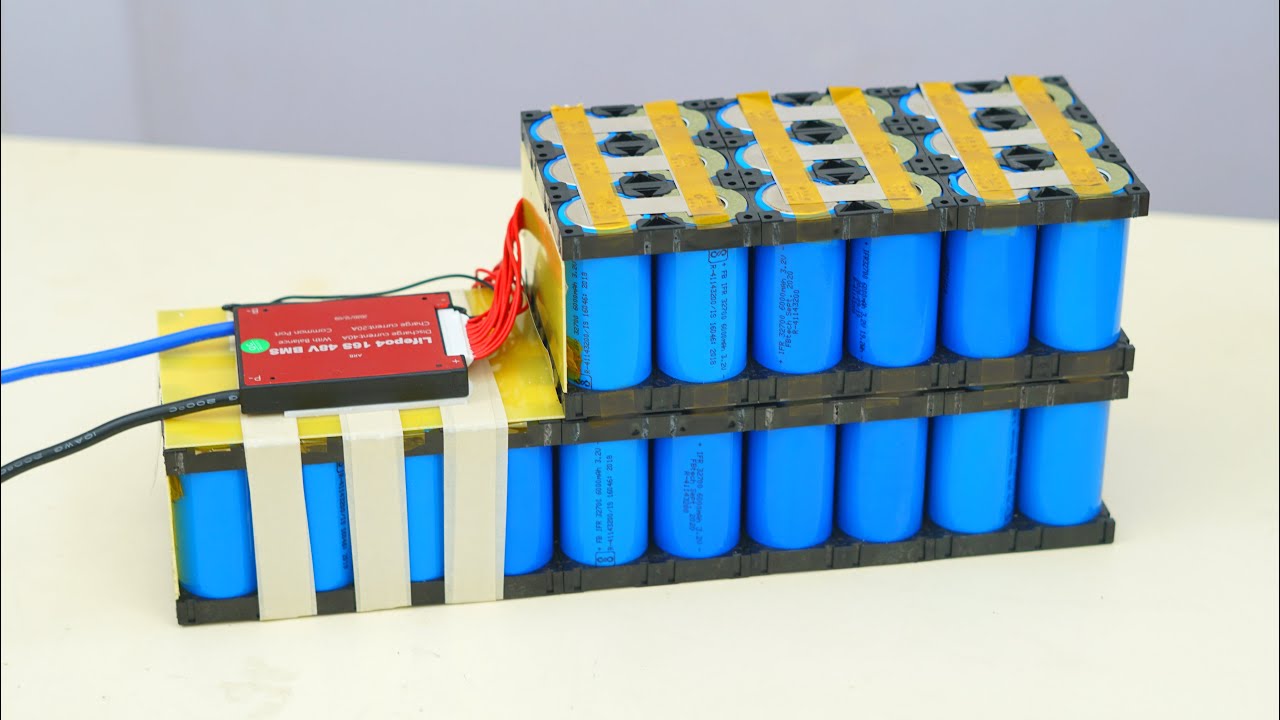

3. Design the Battery Pack Layout

Once you have determined your power requirements and selected the battery chemistry, the next step is to design the layout of your battery pack. Consider factors such as space constraints, cooling requirements, and accessibility for maintenance when laying out the battery cells and modules.

4. Ensure Proper Cell Balancing

Cell balancing is crucial for the performance and longevity of your 48V battery pack. Implement a balancing system to ensure that each cell is charged and discharged evenly, preventing overcharging or overdischarging of individual cells which can lead to premature failure of the battery pack.

5. Implement Safety Features

Safety should be a top priority when designing a 48V battery pack. Implement safety features such as overcurrent protection, overvoltage protection, and thermal management systems to prevent short circuits, overheating, and other potential hazards.

6. Test and Validate the Design

Before deploying your 48V battery pack, it is essential to test and validate the design to ensure it meets your power requirements and safety standards. Conduct thorough testing, including performance testing and safety testing, to identify any potential issues and make necessary adjustments.

7. Monitor and Maintain the Battery Pack

Once your 48V battery pack is in operation, it is crucial to monitor and maintain it regularly to ensure optimal performance and longevity. Implement a monitoring system to track the state of charge, temperature, and health of the battery pack, and perform regular maintenance such as cell balancing and thermal management.

Designing a 48V battery pack requires careful consideration of power requirements, battery chemistry, layout design, safety features, testing, and maintenance. By following these steps and best practices, you can design a reliable and efficient 48V battery pack for your application.

Was this helpful?

0 / 0