How to use a CT sensor for power monitoring?

A Current Transformer (CT) sensor is a useful device that allows you to measure the current flowing through a circuit without breaking the circuit or directly connecting to it. CT sensors are commonly used for power monitoring in electrical systems to help track energy usage, detect power outages, and prevent overloads. In this article, we will discuss how you can use a CT sensor for power monitoring in your applications.

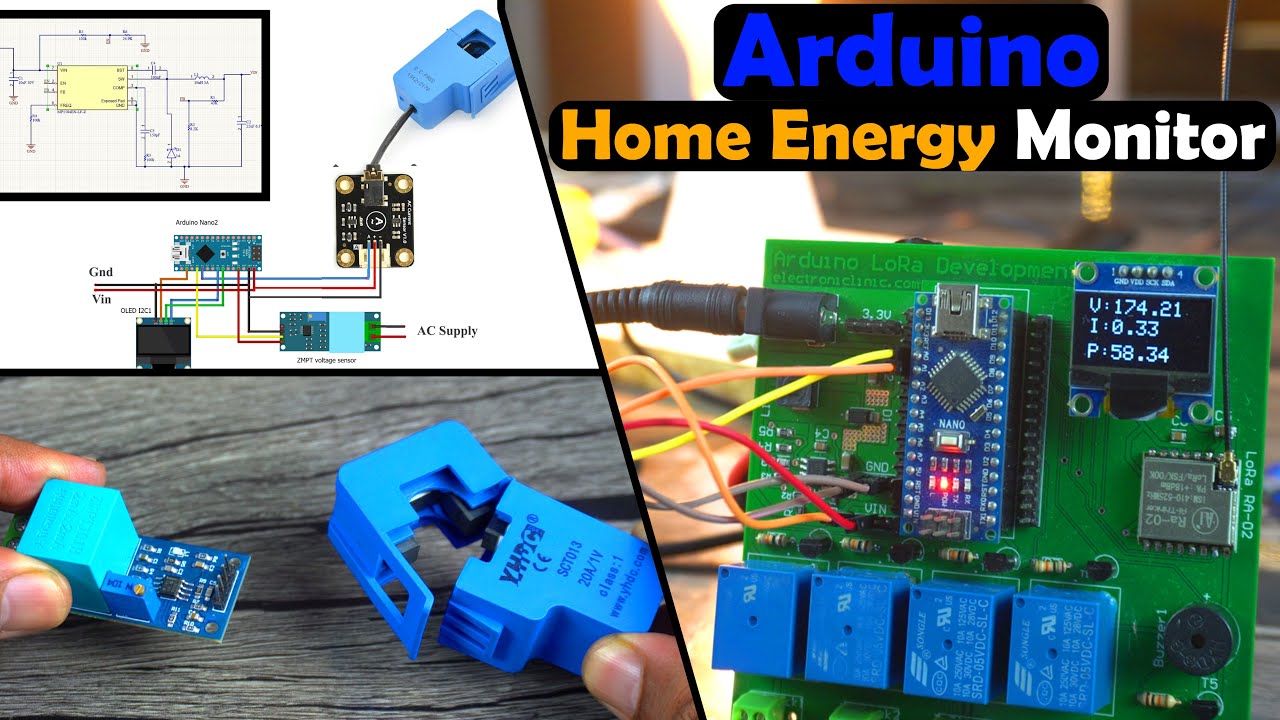

Choose the right CT sensor

Before you start using a CT sensor for power monitoring, it’s essential to choose the right sensor for your application. CT sensors come in different sizes, shapes, and accuracies. Make sure to select a CT sensor that can handle the maximum current rating of your circuit and provides accurate readings. You may also need to consider the type of output signal (e.g., analog or digital) that suits your monitoring system.

Install the CT sensor

Once you have chosen the right CT sensor, the next step is to install it correctly in your electrical system. CT sensors are typically clamped around a single conductor of the circuit you want to monitor. Make sure to follow the manufacturer’s instructions for installation and ensure that the sensor is securely fixed in place.

Calibrate the CT sensor

After installing the CT sensor, you need to calibrate it to ensure accurate measurements. Calibration involves adjusting the sensor to match the actual current flow in the circuit. Some CT sensors come pre-calibrated, while others may require manual calibration using a multimeter or a calibration tool.

Connect the CT sensor to a monitor

Once the CT sensor is installed and calibrated, you can connect it to a monitoring device or system. Depending on the type of output signal, you may need to use a signal conditioner or a data logger to read and store the current measurements. Make sure to follow the manufacturer’s guidelines for connecting the CT sensor to the monitoring system.

Monitor power usage

With the CT sensor connected to the monitoring system, you can now start monitoring power usage in real-time. The monitoring system will display the current flowing through the circuit, allowing you to track energy consumption, identify trends, and detect any anomalies that may indicate power issues.

Set up alerts and notifications

To enhance your power monitoring capabilities, you can set up alerts and notifications based on the current readings from the CT sensor. This can help you proactively identify potential power problems, such as overloads or voltage spikes, and take appropriate action to prevent equipment damage or power outages.

Perform regular maintenance

Lastly, it’s essential to perform regular maintenance on the CT sensor and monitoring system to ensure accurate and reliable power monitoring. Check the sensor for any signs of wear or damage, calibrate it periodically, and update the monitoring system software to ensure it is up to date with the latest features and security patches.

By following these steps, you can effectively use a CT sensor for power monitoring in your applications. Remember to choose the right sensor, install it correctly, calibrate it for accuracy, connect it to a monitoring system, monitor power usage, set up alerts, and perform regular maintenance to keep your power monitoring system running smoothly.

Was this helpful?

0 / 0