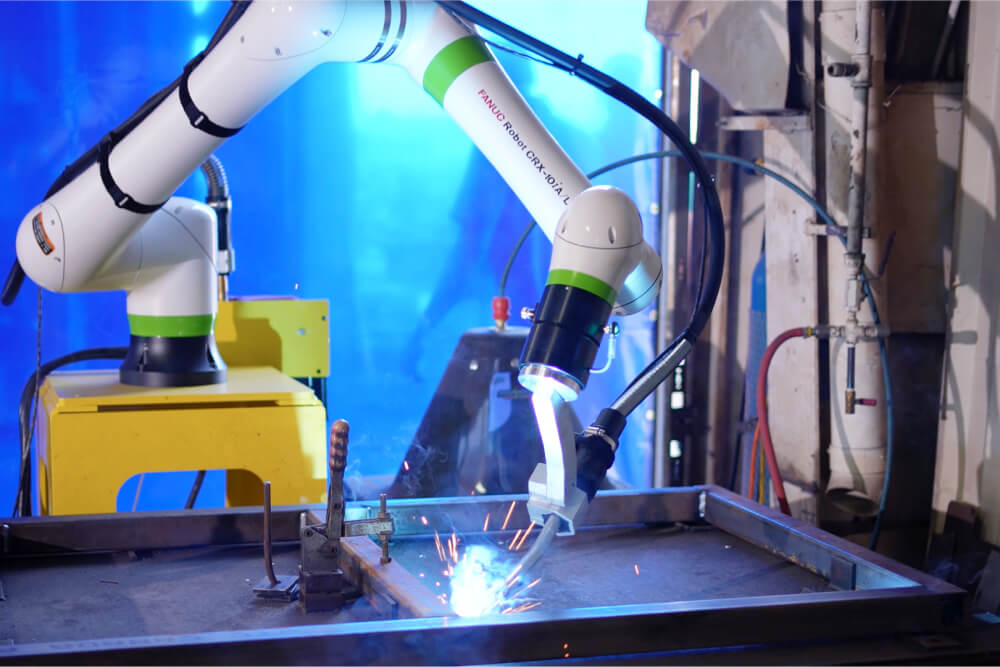

How to set up a Fanuc cobot for collaborative automation?

Collaborative robots, or cobots, have revolutionized the manufacturing industry by working alongside humans to increase productivity and efficiency. Fanuc, a leading provider of industrial automation solutions, offers a wide range of cobots that are easy to set up and program for various applications. In this guide, we will walk you through the process of setting up a Fanuc cobot for collaborative automation.

Step 1: Choose the Right Cobot Model

- Consider the payload and reach requirements for your application.

- Choose a cobot model that is suited to your specific needs.

Step 2: Install the Cobot

Once you have chosen the right cobot model, it’s time to install it in your workspace. Follow the manufacturer’s instructions for mounting the cobot securely and connecting it to power and any necessary peripherals.

Step 3: Program the Cobot

Programming a Fanuc cobot is straightforward, thanks to its user-friendly interface. Use the provided software to teach the cobot specific tasks, such as picking and placing objects, assembling components, or performing quality checks.

Step 4: Test and Optimize Performance

After programming the cobot, it’s essential to test its performance and make any necessary adjustments to ensure optimal efficiency. Monitor the cobot’s movements and interactions with human operators to identify any potential issues.

Step 5: Implement Safety Measures

- Set up safety barriers or sensors to prevent collisions between the cobot and human workers.

- Train employees on how to work safely alongside the cobot.

Step 6: Continuous Monitoring and Maintenance

Regularly monitor the performance of the cobot and perform routine maintenance to keep it running smoothly. Address any issues promptly to avoid costly downtime.

By following these steps, you can set up a Fanuc cobot for collaborative automation and enhance the efficiency of your manufacturing operations. With the right approach and attention to detail, you can maximize the potential of your cobot and improve overall productivity.

Was this helpful?

0 / 0