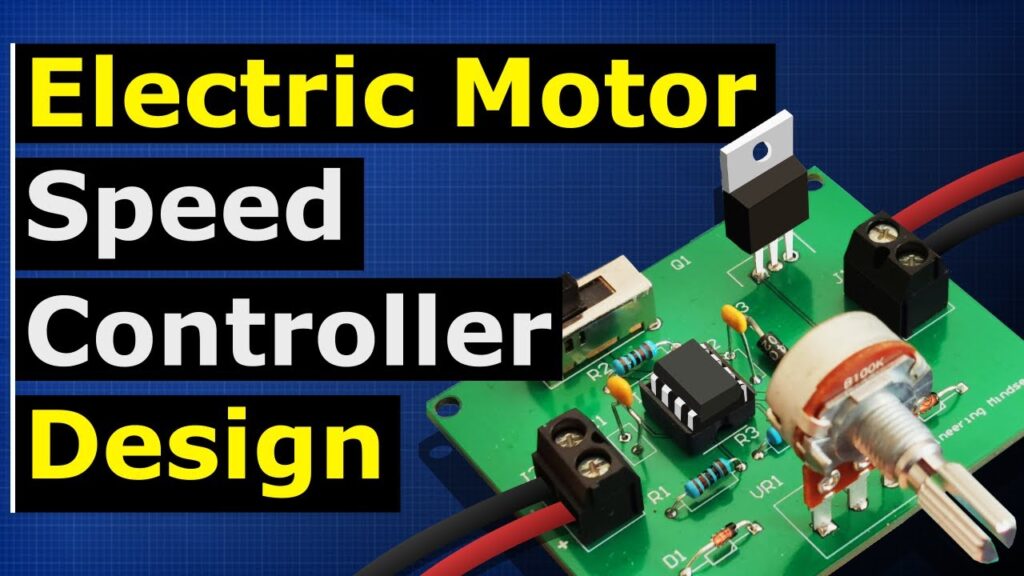

Best way to design a motor speed controller

Designing a motor speed controller is a crucial aspect of any motor-driven system. Whether you are developing a new product or upgrading an existing one, having the right motor speed controller can make a world of difference in terms of performance, efficiency, and reliability.

So, what is the best way to design a motor speed controller? In this article, we will explore some key considerations and tips to help you in the process.

Understand the motor specifications

The first step in designing a motor speed controller is to understand the specifications of the motor itself. This includes parameters such as the voltage rating, current rating, speed range, torque requirements, and type of motor (DC, AC, stepper, etc.). Having a clear understanding of these specifications will help you select the right components and design a controller that meets the motor’s requirements.

Choose the right control algorithm

Once you have a good grasp of the motor specifications, the next step is to choose the right control algorithm for your motor speed controller. There are various control algorithms available, such as PID control, fuzzy logic control, and vector control. Each algorithm has its strengths and weaknesses, so it’s important to select the one that best suits your motor and application requirements.

Select the appropriate components

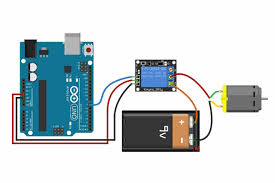

After selecting the control algorithm, the next step is to choose the appropriate components for your motor speed controller. This includes selecting the right microcontroller, power electronics (such as MOSFETs or IGBTs), sensors (such as encoders or Hall effect sensors), and any other necessary components. It’s important to ensure that the components are compatible with each other and can handle the power and voltage requirements of the system.

Implement the control system

Once you have selected the components, the next step is to implement the control system. This involves designing the control circuit, writing the control software, and testing the system to ensure that it meets the motor’s requirements. It’s important to pay close attention to details during this stage to ensure that the control system functions correctly and reliably.

Test and optimize the controller

After implementing the control system, the final step is to test and optimize the motor speed controller. This involves testing the controller under various operating conditions, analyzing the results, and making any necessary adjustments to optimize the controller’s performance. It’s important to thoroughly test the controller to ensure that it meets the motor’s speed, torque, and efficiency requirements.

In conclusion, designing a motor speed controller requires careful consideration of the motor specifications, selection of the right control algorithm and components, implementation of the control system, and thorough testing and optimization. By following these steps and paying attention to detail, you can design a motor speed controller that meets the requirements of your motor-driven system.

Thank you for reading. Stay tuned for more engineering articles.

Best way to design a motor speed controller

Designing a motor speed controller is a crucial aspect of any motor-driven system. Whether you are developing a new product or upgrading an existing one, having the right motor speed controller can make a world of difference in terms of performance, efficiency, and reliability.

So, what is the best way to design a motor speed controller? In this article, we will explore some key considerations and tips to help you in the process.

Understand the motor specifications

The first step in designing a motor speed controller is to understand the specifications of the motor itself. This includes parameters such as the voltage rating, current rating, speed range, torque requirements, and type of motor (DC, AC, stepper, etc.). Having a clear understanding of these specifications will help you select the right components and design a controller that meets the motor’s requirements.

Choose the right control algorithm

Once you have a good grasp of the motor specifications, the next step is to choose the right control algorithm for your motor speed controller. There are various control algorithms available, such as PID control, fuzzy logic control, and vector control. Each algorithm has its strengths and weaknesses, so it’s important to select the one that best suits your motor and application requirements.

Select the appropriate components

After selecting the control algorithm, the next step is to choose the appropriate components for your motor speed controller. This includes selecting the right microcontroller, power electronics (such as MOSFETs or IGBTs), sensors (such as encoders or Hall effect sensors), and any other necessary components. It’s important to ensure that the components are compatible with each other and can handle the power and voltage requirements of the system.

Implement the control system

Once you have selected the components, the next step is to implement the control system. This involves designing the control circuit, writing the control software, and testing the system to ensure that it meets the motor’s requirements. It’s important to pay close attention to details during this stage to ensure that the control system functions correctly and reliably.

Test and optimize the controller

After implementing the control system, the final step is to test and optimize the motor speed controller. This involves testing the controller under various operating conditions, analyzing the results, and making any necessary adjustments to optimize the controller’s performance. It’s important to thoroughly test the controller to ensure that it meets the motor’s speed, torque, and efficiency requirements.

In conclusion, designing a motor speed controller requires careful consideration of the motor specifications, selection of the right control algorithm and components, implementation of the control system, and thorough testing and optimization. By following these steps and paying attention to detail, you can design a motor speed controller that meets the requirements of your motor-driven system.

Thank you for reading. Stay tuned for more engineering articles.