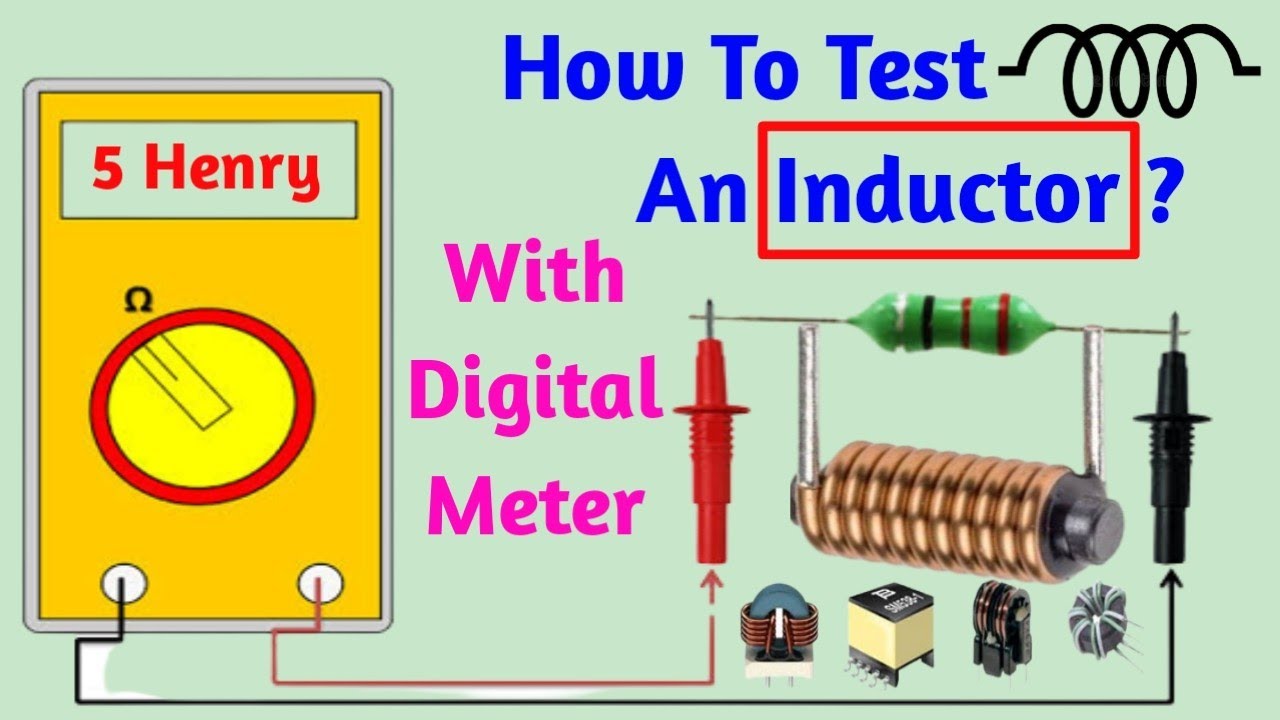

How to Test an Inductor

Inductors are important components in electronics, used to store and release energy in the form of magnetic fields. Testing an inductor is crucial to ensure that it is functioning properly and will not cause any issues in a circuit. In this article, we will discuss various methods to test an inductor to determine its health and performance.

Visual Inspection

The first step in testing an inductor is to visually inspect it for any physical damage or signs of wear. Look for any burnt marks, cracks, or deformities that may indicate a problem with the inductor. If you notice any damage, it is best to replace the inductor.

Resistance Measurement

One of the most common ways to test an inductor is by measuring its resistance. This can be done using a multimeter in resistance mode. Simply place the multimeter leads across the terminals of the inductor and check the reading. A normal inductor should have a resistance within a certain range, depending on its specifications.

If the resistance reading is significantly different from the expected value, it may indicate a problem with the inductor. This could be due to a short circuit, open circuit, or a damaged winding. In such cases, it is best to replace the inductor.

Inductance Measurement

Another important parameter to test in an inductor is its inductance. Inductance can be measured using an inductance meter or an LCR meter. Simply connect the meter leads to the terminals of the inductor and check the reading. The inductance value should be within the specified range for the inductor.

If the inductance reading is outside the expected value, it may indicate a problem with the inductor. This could be due to a shorted winding, a broken core, or other issues. In such cases, it is best to replace the inductor to ensure proper circuit operation.

Frequency Response Test

Inductors have a frequency-dependent behavior, so it is important to test their performance at different frequencies. A frequency response test can be performed using an LCR meter or a signal generator. By varying the frequency and measuring the inductance at each frequency, you can determine how the inductor responds to different frequencies.

If the inductor shows significant deviations in inductance at different frequencies, it may indicate a problem with the inductor. This could be due to parasitic capacitance, core saturation, or other factors. In such cases, it is best to replace the inductor for optimal circuit performance.

Core Saturation Test

Core saturation is a common issue in inductors, where the magnetic core becomes saturated and unable to store additional magnetic energy. To test for core saturation, you can apply a gradually increasing DC current to the inductor and measure the inductance. If the inductance drops significantly at higher currents, it may indicate core saturation.

If core saturation is detected, it is best to replace the inductor with a higher-rated one that can handle the required current without saturation. This will ensure that the inductor operates within its specified limits and does not cause any issues in the circuit.

Temperature Test

Temperature can also affect the performance of an inductor, especially in high-power applications. To test the temperature performance of an inductor, you can measure the inductance at different temperature points using a temperature-controlled chamber or a heat gun.

If the inductance of the inductor varies significantly with temperature, it may indicate a problem with the inductor’s core material or winding. In such cases, it is best to replace the inductor with a higher-quality one that can withstand temperature variations without affecting its performance.

Conclusion

In conclusion, testing an inductor is essential to ensure its proper function and reliability in a circuit. By performing visual inspections, resistance measurements, inductance measurements, frequency response tests, core saturation tests, and temperature tests, you can determine the health and performance of an inductor. If any issues are detected during testing, it is best to replace the inductor to prevent any potential problems in the circuit.

Was this helpful?

0 / 0