Best Way to Test a Capacitor

Capacitors are essential components in electronic circuits, storing and releasing electrical energy. However, like any other electronic component, capacitors can fail over time. Testing a capacitor is crucial to ensure your circuit functions properly and prevent any damage that may result from a faulty capacitor. In this article, we will discuss the best way to accurately test a capacitor.

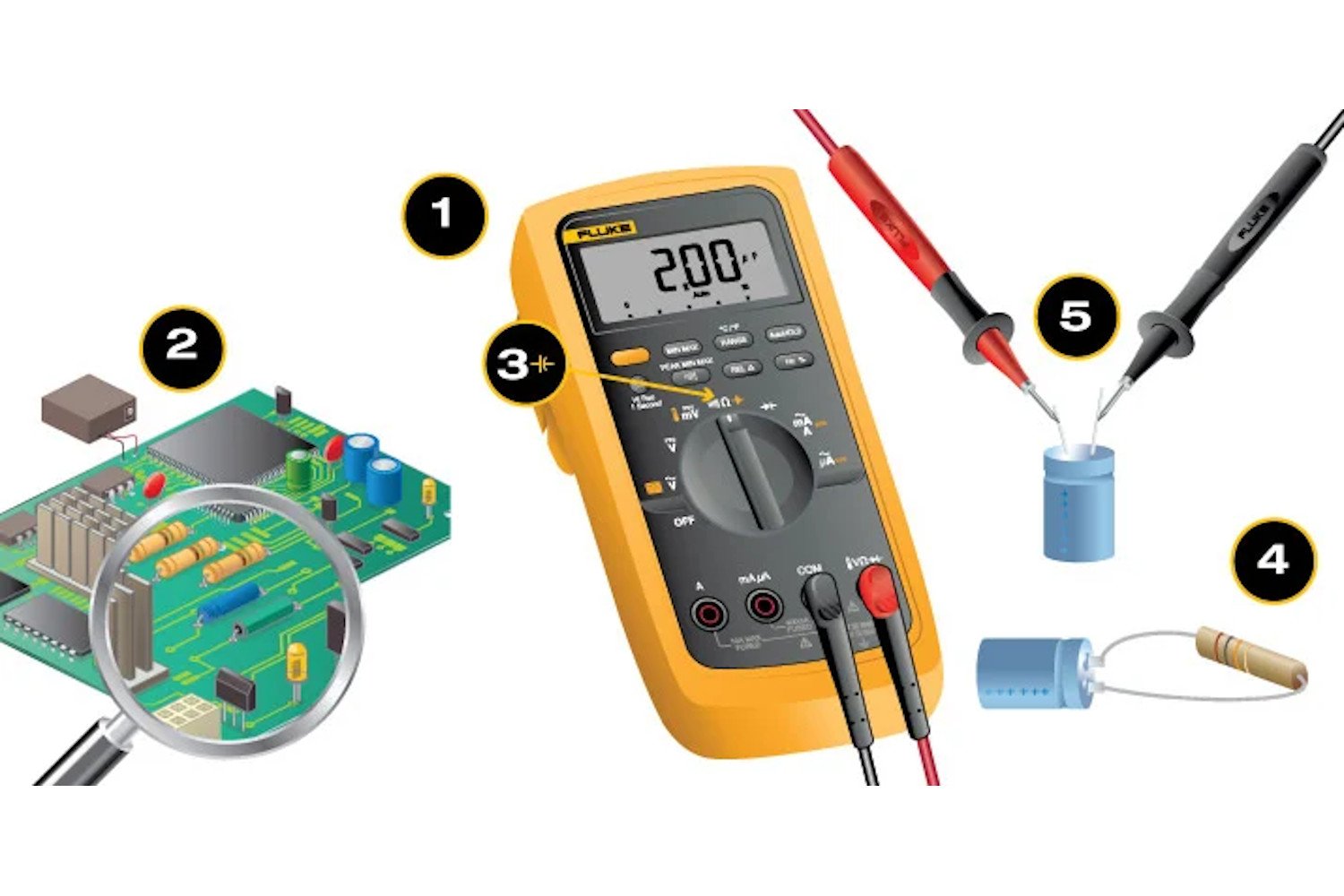

1. Visual Inspection

Before testing a capacitor, it’s essential to perform a visual inspection. Look for any signs of physical damage such as bulging, leakage, or discoloration. These are clear indicators that the capacitor has failed and needs to be replaced. In such cases, testing the capacitor may not be necessary.

2. Using a Multimeter

One of the most common methods to test a capacitor is by using a multimeter. Set the multimeter to the capacitance mode and connect the probes to the capacitor terminals. The multimeter will display the capacitance value, allowing you to determine if the capacitor is within the specified range. If the capacitance reading is significantly lower or higher than the rated value, it may indicate a faulty capacitor.

3. Using an ESR Meter

Another reliable method to test a capacitor is by using an ESR (Equivalent Series Resistance) meter. This tool measures the internal resistance of the capacitor, providing valuable information about its condition. A high ESR reading indicates a faulty capacitor that needs to be replaced.

4. Discharge the Capacitor

Before testing a capacitor, it’s crucial to discharge it to avoid any electrical shock. Use a resistor to discharge the capacitor slowly and safely. Once the capacitor is discharged, you can proceed with the testing process.

5. Performing a Leakage Test

Capacitors are prone to leakage, which can affect their performance. To perform a leakage test, connect the capacitor to a high-value resistor and monitor the voltage across the capacitor. If the voltage drops significantly over time, it indicates leakage, and the capacitor should be replaced.

6. Temperature Testing

Testing a capacitor at different temperatures can provide additional insights into its reliability. Heat the capacitor using a heat gun or a hairdryer and measure its capacitance. A significant change in capacitance at higher temperatures may indicate a faulty capacitor.

7. Professional Testing

If you have access to specialized equipment, such as a capacitor analyzer, consider performing a professional test. These tools provide detailed information about the capacitor’s condition and can help you make informed decisions about its replacement.

Conclusion

Testing a capacitor is essential to ensure the proper functioning of your electronic circuits. By following the methods mentioned above, you can accurately test a capacitor and identify any faulty components. Remember, always prioritize safety when working with capacitors and consult a professional if you are unsure about the testing process.

Was this helpful?

0 / 0